From Loose Grains to Fixed Grains

Grinding Support

Safety

Miscellaneous Information

Information on fixed abrasives

- Catalog Download

- List of Catalog Download

- Grinding & Polishing Technical Information "NORITAKE TECHNICAL JOURNAL"

- About Our Sales Offices

From loose grains to fixed grains. Noritake offers fixed-grain tools for processes in which loose grains were previously used.

Customers can make plans to reduce manufacturing costs and waste materials by switching to methods that use fixed-abrasive tools.

Diamond Wire

Diamond wire consists of a piano wire core with affixed diamond grains. Diamond tools are used to slice all kinds of materials, such as silicon and sapphire.

Using this diamond wire improves productivity compared to methods based on loose grain systems by improving machining efficiency and providing consistent machining precision. Since slurry isn’t required, diamond wire lets companies make significant reductions to their environmental impact.

Applications

Slicing silicon for solar cells, sapphire for LEDs and more

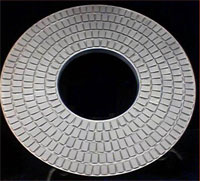

Metal Grinding Wheels for Fixed Diamond Lapping

We’ve developed metal grinding wheels for fixed diamond lapping as a tool to be used for lapping highly brittle materials like ceramics. The fixed diamond grain of these wheels results in enormous improvements in machining efficiency. Even the work environment can be expected to improve.

Applications

Lapping of glass, crystal, ceramics, etc.

Super-Precise Surface Grinding Wheel “Nano-Finisher”

The Nano-Finisher is a grinding wheel with nanometer-level vitrified super-fine granules that can be installed in super-precise grinding machines. This can replace loose grain machining for any lapping or pre-polishing process and offers a significant reduction in the number of required processes.

Applications

Lapping silicon wafers, glass, quartz substrates, etc.