Porous ceramic component

Ceramics & Materials

- Electronic Paste (Thick Film)

-

Engineering Ceramics

- Engineering Ceramics List

- Ceramic cores for precision casting

- Porous ceramic component

- Thick Film Circuit Substrate

- Gypsum

- Decoration Materials

- Electronic Ceramic Powder

- Vacuum Fluorescent Display

- Dental Materials

- Technical Support

- Technical Support List

- What is decalcomania?

- Thick Film Circuit Substrate with Precious Metal design guidance

- About Our Technology

- New Copper Conductors + Plating Substrate design guidance

- Thick Film Circuit Substrate with Copper Conductors design guidance

- Thick Film Heater design guidance

- Catalog Lineup

- Pore size control for porous ceramic components

- Core Material Characteristics

- ℃ MONARC Characteristics

- Catalog Download

- About Our Sales Offices

-

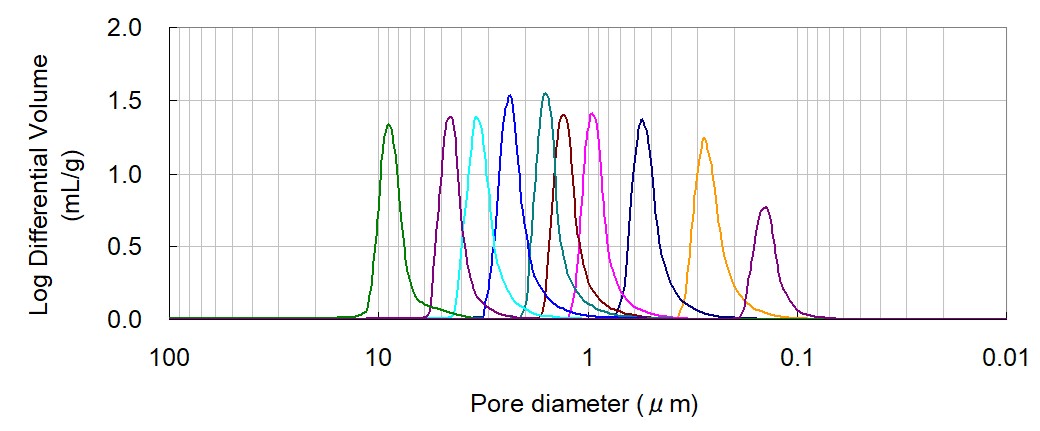

Porous ceramic components have small pores. Noritake has technologies for controlling the pore size distribution and volume in a sophisticated manner. Porous ceramic components continue to play an active role as catalyst, filler for filtration and sorbent applications in chemical engineering and electronics.

Pore size control for porous ceramic components

Noritake’s technology of controlling small pore size and volume enables to meet requirements for manufacturing porous ceramic components with various pore size distribution.

<Example of pore size distribution for porous ceramic components>