PRODUCTS

Fuel Cell

Engineering

-

Heating Furnaces / Kilns

- Heating Furnaces / Kilns List

-

Drying Furnace

- Drying Furnace List

- Batch Kiln

- Far Infrared Conveyer Furnace

- Other Drying Furnaces

- Roll to Roll Far-infrared Heating Furnace

- Far Infrared Heater

-

Firing Kiln

- Firing Kiln List

- Roller Hearth Kiln

- Pusher Kiln

- Rotary Kiln

- Other

- Batch Kiln

- Refractory

-

Search by industry or usage

- Search by industry or usage List

- Semiconductors

- Energy

- Electronics

- Automobiles

- Displays and lighting

- Other

- Furnace Construction Maintenance

-

Mixing Technology

- Mixing Technology List

-

SM Engineering Equipment

- SM Engineering Equipment List

-

Heating and Cooling Systems

- Heating and Cooling Systems List

- Saccharification system for bio-ethanol production

- Adhesive Temperature Adjusting System

- Coating Liquid Precision Temperature (viscosity) Adjusting System

- Scrambled Eggs Continuation Manufacturing System

- Condiment Miso Heat Sterilization System

- Starch Gelatinization System for Paper Manufacturing

- Flour Paste Manufacturing System

- PVA Continuous Dissolution System

- Seasoning Liquid Heating Sterilization Cooling System

- Automated Oxidized Starch Production System

- In-line Starch Saccharification System

- Water Heating System

- Mixing Systems

- Powder and Liquid Dispersion System

- Reaction System

- Laboratory Test Systems

-

Heat Exchangers

- Heat Exchangers List

- Heat Exchangers

- Reaction

-

Static Mixer (SM)

- Static Mixer (SM) List

- Gas absorption(Option)

- Homogenization

- Miixing

- Option Parts

- Search by industry or usage

- Cooker / Steam Mixer

- Cutting Machine (Thin Cut Master : TCM)

-

Filtration Systems

- Filtration Systems List

- Search lubricants

-

Coolant Filtration Systems

- Coolant Filtration Systems List

- Centrifuge

- Coolant Tank Unit

- Magnetic Separator

- Cyclone Separator

- Paper Filter

- Backwash Filter

- Centralized Filtration Systems

- Search filtration materials

- Filtration Related Systems

- Ceramic filter

- Technical Support

- Catalog Download

- About Our Sales Offices

Technical Support

Roller Hearth Kiln for firing SOFC electrolyte

Specification

| Temperature | Max.1500°C |

|---|---|

| Atmosphere in kiln | Air |

Features

- High speed firing

- Uniform temperature distribution

- Stable dimensional accuracy

- Energy saving

Batch Kiln for firing SOFC interconnector

Specification

| Temperature | Max.1700°C |

|---|---|

| Atmosphere in kiln | Air |

| Heat source | Electricity or Gas |

Features

- Uniform temperature distribution

- Rapid heating/Rapid cooling is possible

Roller Hearth Kiln for SOFC electrode firing

Specification

| Temperature | Max.1400°C |

|---|---|

| Atmosphere in kiln | Air |

Features

- Uniform temperature distribution

- Rapid heating/Rapid cooling is possible

- Energy saving

Batch Kiln for firing PEFC carbon separator

Specification

| Temperature | Max.1000°C |

|---|---|

| Atmosphere in kiln | Nitrogen |

| Kiln material | Carbon |

Features

- Low oxygen concentration control

- High accuracy atmosphere control

- Rapid heating/Rapid cooling is possible

Far Infrared Conveyer Furnace for drying PEFC carbon separator

Specification

| Temperature | Max.230°C |

|---|---|

| Atmosphere in kiln | Air |

| Heat source | Electricity |

Features

- Uniform temperature distribution

- Quick drying

- Energy saving

Far-infrared Clean Conveyer Furnace

| Working temperature | R.T.~400°C |

|---|---|

| Temperature precision | ±5°C |

| Atmosphere | Air, N2 |

| Heat source | Electricity |

| Clean level | Class 100 |

| Heating method | Far infrared heater + Hot air |

Continuous type Epoxy Curing Furnace

| Heating method | Far infrared + Hot air ciuculation |

|---|---|

| Temperature | Max.400°C |

| Temperature accuracy | ±3°C (at400°C) |

Roll to Roll Special Atmosphere Furnace

| Working temperature | R.T.~400°C |

|---|---|

| Temperature precision | ±5°C |

| Atmosphere | Air, N2 (Option) |

| Clean level | Class 1000 |

| Film width | 600~1200mm |

| Conveyance tension | 10~100N |

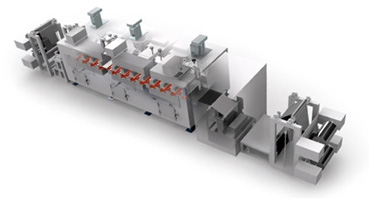

Fuel Cell Electrode Drying Furnace

Drying Furnace for Coated Film

-

High-efficient drying furnace for coated film which consists of explosion-proof far-infrared heaters and a special conveying system.

[Application] Pre-drying of solvent coated on Li-ion battery electrode

Max.Temperature 250°C Heater Explosion-proof far-infrared heater

Vacuum Drying Furnace

Vacuum drying furnace with our original chamber structure can drastically decreases the heating/cooling time.

[Application] Li-ion battery electrode pre-assembly drying

| Max.Temperature | 200°C |

|---|---|

| Vacuum range | Atmosphere pressure - 1Pa |