- HOME

- Product Information

- Engineering

- Mixing Technology

- Static Mixer (SM)

- Option Parts

- Injection tees

PRODUCTS

Injection tees

Engineering

-

Heating Furnaces / Kilns

- Heating Furnaces / Kilns List

-

Drying Furnace

- Drying Furnace List

- Batch Kiln

- Far Infrared Conveyer Furnace

- Other Drying Furnaces

- Roll to Roll Far-infrared Heating Furnace

- Far Infrared Heater

-

Firing Kiln

- Firing Kiln List

- Roller Hearth Kiln

- Pusher Kiln

- Rotary Kiln

- Other

- Batch Kiln

- Refractory

-

Search by industry or usage

- Search by industry or usage List

- Semiconductors

- Energy

- Electronics

- Automobiles

- Displays and lighting

- Other

- Furnace Construction Maintenance

-

Mixing Technology

- Mixing Technology List

-

SM Engineering Equipment

- SM Engineering Equipment List

-

Heating and Cooling Systems

- Heating and Cooling Systems List

- Saccharification system for bio-ethanol production

- Adhesive Temperature Adjusting System

- Coating Liquid Precision Temperature (viscosity) Adjusting System

- Scrambled Eggs Continuation Manufacturing System

- Condiment Miso Heat Sterilization System

- Starch Gelatinization System for Paper Manufacturing

- Flour Paste Manufacturing System

- PVA Continuous Dissolution System

- Seasoning Liquid Heating Sterilization Cooling System

- Automated Oxidized Starch Production System

- In-line Starch Saccharification System

- Water Heating System

- Mixing Systems

- Powder and Liquid Dispersion System

- Reaction System

- Laboratory Test Systems

-

Heat Exchangers

- Heat Exchangers List

- Heat Exchangers

- Reaction

-

Static Mixer (SM)

- Static Mixer (SM) List

- Gas absorption(Option)

- Homogenization

- Miixing

- Option Parts

- Search by industry or usage

- Cooker / Steam Mixer

- Cutting Machine (Thin Cut Master : TCM)

-

Filtration Systems

- Filtration Systems List

- Search lubricants

-

Coolant Filtration Systems

- Coolant Filtration Systems List

- Centrifuge

- Coolant Tank Unit

- Magnetic Separator

- Cyclone Separator

- Paper Filter

- Backwash Filter

- Centralized Filtration Systems

- Search filtration materials

- Filtration Related Systems

- Ceramic filter

- Technical Support

- Catalog Download

- About Our Sales Offices

Technical Support

-

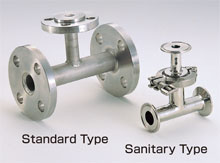

These Injection tees are inlets special l y designed to allow the maximum mixing effect of the static mixer.

We recommend their use for applications that have large fluid flow ratios.

-

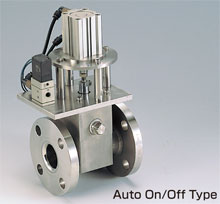

This type has an automatic On/Off switch at the tip of the injection tee’s inlet nozzle.

This prevents the main fluid from flowing to the inlet side when the infusion is stopped.

Standard Specifi cations

| Material | 304 S.S, Ferrule |

|---|---|

| Fixing | JIS 10K Flange |

PAT.2045307

Model Code Chart

When installed with a Static Mixer.

A“ /T” is added to the end of the Static Mixers Model Number.

Example) 1-N60-331-1/T

Model Code Chart

Dimensions

Standard Type

| Model | Nominal Diameter (ND) (1) |

Amm |

Bmm |

|---|---|---|---|

| T-□/15-3 | 1/2" | 90 | 80 |

| T-□/20-3 | 3/4" | 90 | 80 |

| T-□/25-3 | 1" | 110 | 100 |

| T-□/40-3 | 1 1/2" | 110 | 100 |

| T-□/50-3 | 2" | 140 | 115 |

| T-□/65-3 | 2 1/2" | 150 | 120 |

| T-□/80-3 | 3" | 150 | 120 |

| T-□/100-3 | 4" | 160 | 150 |

| T-□/125-3 | 5" | 180 | 170 |

| T-□/150-3 | 6" | 190 | 180 |

| T-□/200-3 | 8" | 240 | 230 |

Size of flange (2) is decided by the conditions of the flow.

Sanitary Type

| Model | Nominal Diameter (ND) (1) |

Amm |

Bmm |

Cmm |

Dmm |

|---|---|---|---|---|---|

| T-□/25-3/S | 1S | 55 | 55 | 53 | 110 |

| T-□/40-3/S | 1 1/2S | 70 | 70 | 53 | 125 |

| T-□/50-3/S | 2S | 82 | 82 | 56 | 140 |

| T-□/65-3/S | 2 1/2S | 105 | 105 | 58 | 165 |

| T-□/80-3/S | 3S | 110 | 110 | 58 | 170 |

Size of flange (2) is decided by the conditions of the flow.

Joint can be changed to IDF Screw & Nut

Auto On/Off Type

| Model | Nominal Diameter (ND) (1) |

Amm |

Bmm |

|---|---|---|---|

| TA-□/25-3 | 1" | 40 | 60 |

| TA-□/40-3 | 1 1/2" | 50 | 75 |

| TA-□/50-3 | 2" | 100 | 100 |

| TA-□/65-3 | 2 1/2" | 100 | 150 |

| TA-□/80-3 | 3" | 100 | 150 |

| TA-□/100-3 | 4" | 135 | 150 |

| TA-□/125-3 | 5" | 145 | 150 |

| TA-□/150-3 | 6" | 170 | 150 |

| TA-□/200-3 | 8" | 195 | 150 |

| TA-□/250-3 | 10" | 205 | 150 |

| TA-□/300-3 | 12" | 260 | 150 |

| TA-□/350-3 | 14" | 280 | 150 |

Size of flange (2) is decided by the conditions of the flow.Joint can be changed to ferrule type.