News Release

1/24/2025

NORITAKE CO., LIMITED

Successful Prototyping of a New Phosphorus-Free Glass Material Bondable to Aluminum at 300–350℃

– Utilizing Materials Informatics Based on 120 Years of Data –

NORITAKE CO., LIMITED (Headquarters: Nagoya, Aichi; Representative Director and President: Akira Higashiyama; hereinafter referred to as “Noritake”) has been utilizing Materials Informatics*1 (MI) since 2023 to develop new materials. As a result, Noritake has successfully prototyped a new phosphorus-free glass material that can be bonded to aluminum at low temperatures.

Market Environment

Amid the growing trend of EVs and automotive electrification, the use of power semiconductors capable of handling high voltage and large currents is expected to increase.

In general, phosphorus contamination affects performance of semiconductors.

In addition, because of the growing demand for vehicle weight reduction, it is expected that the use of lightweight aluminum in peripheral components*2 will increase.

Challenges in Bonding Aluminum

When aluminum is used as a component material, organic materials (resins) are typically used for bonding. However, for peripheral materials of next-generation power semiconductors, the operating environment can reach high temperatures, causing common resin materials to degrade easily because their heat resistance temperature*3 is about 200℃. Therefore, bonding with heat-resistant inorganic materials (such as glass) is expected to provide an effective solution.

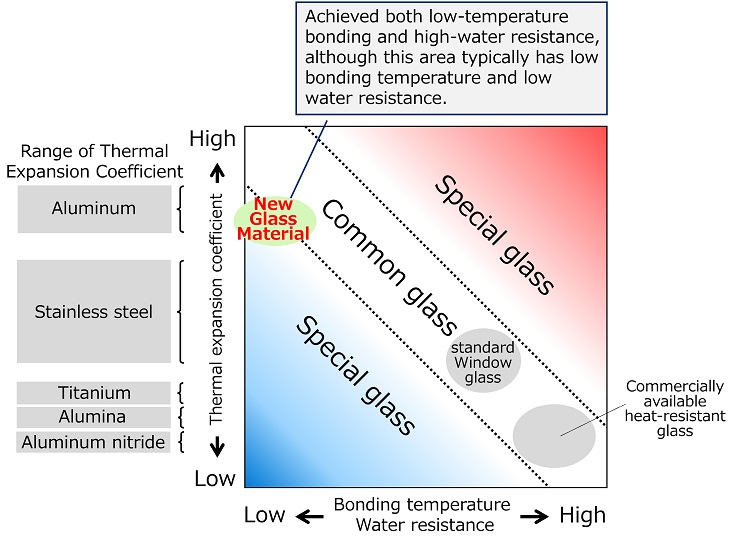

In environments like automotive applications, where temperatures fluctuate, matching the thermal expansion coefficient*4 of the bonding material with that of aluminum can prevent peeling and cracking.

Since aluminum has a high thermal expansion coefficient, the glass material used as a bonding agent also needs to have a comparable coefficient.

However, there is a challenge in achieving both low-temperature bonding (400℃ or below) and high-water resistance simultaneously.

Succeeded in Rapid Prototyping by Leveraging Noritake’s Expertise and MI

(Bonded with aluminum after heating to 300℃)

Material development involves optimizing compositions from a vast combination of elements to achieve desired properties, which is a challenging task. In addition, glass materials are particularly difficult to optimize due to the considerable number of elements involved. To address this challenge, Noritake utilized Materials Informatics (MI) and its extensive accumulated data on glass materials, enabling the successful prototyping of new glass materials in a short period.

Features of the New Glass Material

① Bonding Achievable at 300–350℃

・Can withstand environments of up to about 300℃ such as periphery of next generation power semiconductors

・Suitable for use with aluminum

(Aluminum deteriorates when it is cooled after heat treatment at approximately 400℃ or above)

② Combines Low-Temperature Bonding with High Water Resistance

・Optimized composition allows it to be used in normal air environment.

③ Phosphorus-Free

・Does not interfere with semiconductor performance during manufacturing or use.

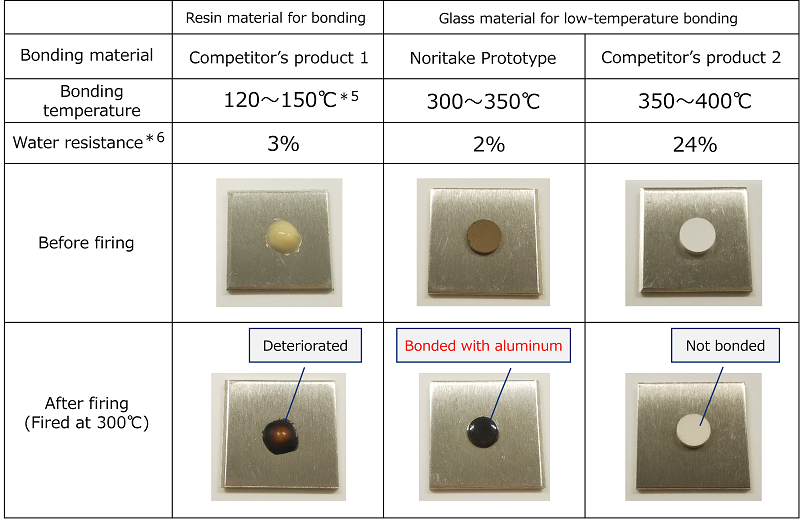

Performance Comparison with Other Products

(Based on internal testing by Noritake)

*1 A method to accelerate materials development by utilizing information science technologies, such as AI.

*2 Source: Aluminum VISION 2050 (Japan Aluminum Association)

*3 The temperature at which degradation begins when the material is heated from room temperature.

*4 A value that indicates how much the substance expands when the room temperature increases by 1℃.

*5 Standard curing temperature range.

*6 The rate of weight change before and after immersion in hot water (90℃) for 24 hours.The smaller the rate of change, the higher the water resistance.

Contact Information

NORITAKE CO., LIMITED Research & Development Center

E-mail:kaihatsu_b9700@noritake.com