PRODUCTS

Grinding & Polishing Technical Information "NORITAKE TECHNICAL JOURNAL"

Grinding and Polishing Tools

- Grinding & Polishing Technical Information "NORITAKE TECHNICAL JOURNAL"

- Technical Support

- About Our Sales Offices

Grinding Solutions

Grinding Solutions

Grinding wheels, dressers, coolants, and filtration equipment that address concerns for each production process and component.

【Catalog preview】

①Product List

Overview of recommended grinding tools, coolants, and filtration equipment for optimization of each process or part.

【Catalog preview】

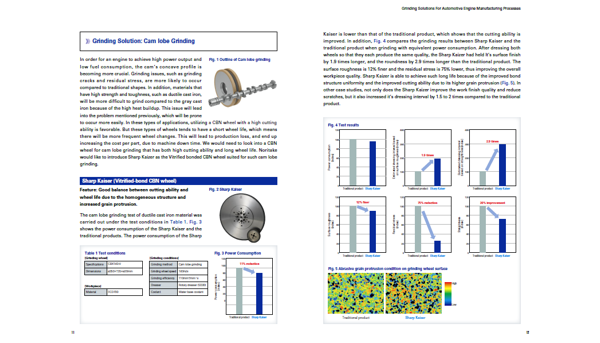

②Product Description

Detailed grinding performance data and descriptions for items in overview.

Grinding Solutions For Automotive Engine Manufacturing Processes

Products that address common issues with automotive engine manufacturing process.

Grinding Solutions For Cutting Tool Manufacturing Process

NEW!

Products that address commom issues with cutting tool manufacturing process.