News Release

2/17/2026

NORITAKE CO., LIMITED

Development of a Conductive Adhesive for Automotive Electronics

- Contributing to the Advancement of Autonomous Driving Technologies -

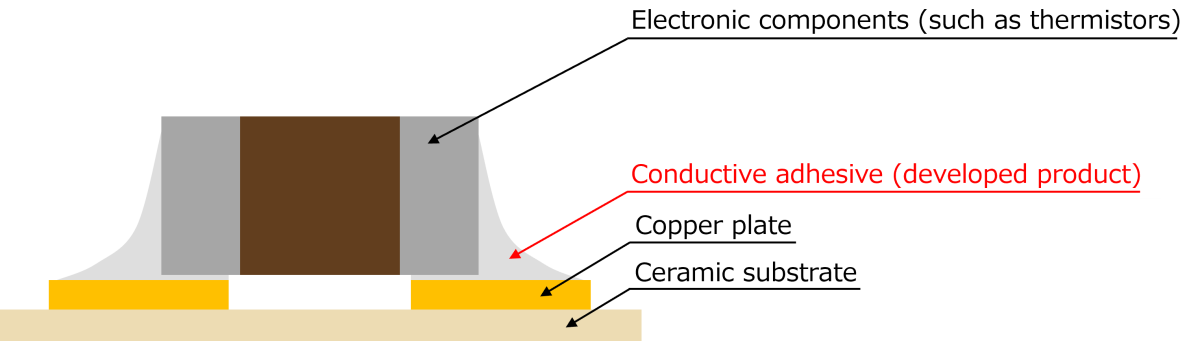

NORITAKE CO., LIMITED (Headquarters: Nagoya, Aichi; Representative Director and President: Akira Higashiyama) has developed a conductive adhesive capable of withstanding operating temperatures of up to 175°C. This adhesive is used to mount electronic components such as thermistors*1 installed in power semiconductor modules, contributing to the advancement of vehicle intelligence and the electrification of vehicles (EVs).

Market Environment

In recent years, with advances in autonomous driving technologies and the electrification of vehicles, the adoption of power semiconductors capable of handling high voltages and large currents is expected to increase. Because power semiconductors operate at high temperatures, electronic components installed near power semiconductors are also required to have higher heat resistance. For example, to meet these requirements, thermistors used for temperature measurement are being developed to withstand operating temperatures of up to 175°C. Consequently, the materials used to mount electronic components on substrates are also required to exhibit high heat resistance.

Challenges in Operating Electronic Components at High Temperatures

Conventionally, solder has been used to mount electronic components on substrates. In power semiconductor modules, not only do temperatures rise during operation, but temperature cycling is also significant. The typical operating temperature of general-purpose solder is approximately 125°C, which is unsuitable for environments where power semiconductors may exceed 170°C. In addition, temperature fluctuations can cause cracks in solder joints, posing a reliability issue.

Highlights of the Newly Developed Product

Through proprietary composition design and particle dispersion technology, the newly developed conductive adhesive achieves both high heat resistance and durability under wide temperature fluctuations. This adhesive enables the reliable mounting of high-temperature-compatible electronic components, such as thermistors, onto substrates.

<Evaluation of Adhesive Performance for Thermistors*2>

①Achieved an Operating Temperature Range Guaranteed for Mounting: -55°C to 175°C

Even at 175°C, changes in characteristics are minimal (resistance change within ±5%), enabling highly reliable temperature sensing.

②Contribution to Defect Reduction

No cracks due to thermal stress*3 were observed even after temperature cycling between -55°C and 175°C.

*1 A temperature sensor whose resistance value changes in response to heat.

*2 The evaluation results described in this release are based on tests conducted by TDK Corporation under the following conditions:

①After measuring the initial resistance at 25°C, a continuous exposure test was conducted for 1,000 hours at a high-temperature environment of 175°C, followed by a second resistance measurement at 25°C to evaluate changes before and after the test.

②A thermal shock test cycling between -55°C and 175°C was repeated 2,000 times, and no defects were detected.

*3 Stress generated inside a material due to differences in expansion and contraction with surrounding materials when exposed to temperature changes.