News Release

6/16/2025

NORITAKE CO., LIMITED

Silver Paste Bonding Material for Automotive Power Semiconductors

- Joint Development with LG Chem, Achieving Long-term Room Temperature Storage -

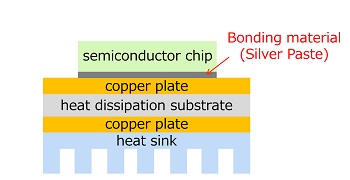

NORITAKE CO., LIMITED (Headquarters: Nagoya, Aichi; Representative Director and President: Akira Higashiyama; hereinafter referred to as “Noritake”) has jointly developed a bonding material for automotive power semiconductors with LG Chem Ltd. (Headquarters: Seoul, South Korea; CEO: Shin Hak-Cheol; hereinafter referred to as “LG Chem”). The newly developed product is a silver paste designed to bond semiconductor chips to copper plates. By combining Noritake’s particle dispersion technology with LG Chem’s particle design technology, the product achieved long-term storage of six months at room temperature.

Market Environment

As the shift toward automotive EVs and electrification continues, the use of power semiconductor modules capable of handling high-voltage and large-current applications is on the rise. Conventionally, semiconductor chips and copper plates in these modules have been bonded with solder paste. However, there is a problem in terms of heat resistance. Since the heat resistance of solder paste is around 215°C while the operating temperatures of power semiconductors can reach as high as 300°C, solder paste tends to deteriorate. Therefore, there is a growing demand for high-temperature bonding materials, such as silver paste.

Challenges of Developing Silver Paste Bonding Materials

While silver paste has high heat resistance, it requires high heating temperatures during bonding, which can lead to degradation of the bonded components. Therefore, it is important to lower the bonding temperature to avoid damaging the components. In recent years, the use of silver nanoparticles as a material has been attempted to lower the bonding temperature. However, when nanoparticles are used, frozen storage at -10°C or below is required to maintain stable quality. Additionally, extending the shelf life is another key challenge as the typical shelf life is approximately three months.

Product Features

The new product achieved long-term storage at room temperature. This was made possible by combining Noritake’s particle dispersion technology and LG Chem’s particle design technology to design the optimal composition. This approach successfully addressed storage challenges without compromising bonding performance.

① Room Temperature Storage*1

The product can be stored at room temperature, which contributes to reducing transportation and storage costs.

② Shelf Life Doubled

The shelf life has been extended from conventional three months to approximately six months, reducing the risk of product disposal.

*1 Store at 25°C or below.