What is ceramics filter ?

Heating Furnaces / Kilns

Mixing Technology

Filtration Systems

- Catalog Download

- About Our Sales Offices

What is a ceramic filter?

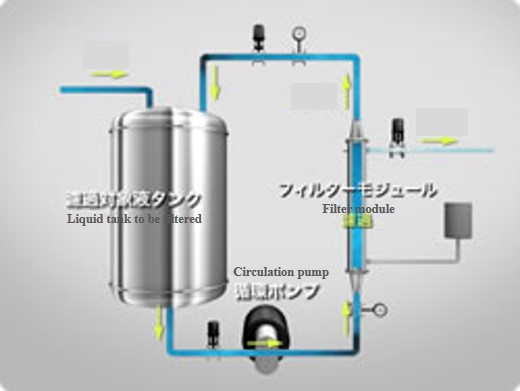

It is a microfiltration device that uses a ceramic membrane as a filter, and is used for separating and concentrating various raw materials and recycling various processing and cleaning liquids. By separating and concentrating raw materials, it leads to improvement of product quality and creation of added value. In addition, filtering waste liquid leads to waste reduction and environmental protection.Since the filter element is made of fine ceramics, it has excellent durability. Taking advantage of this, it is possible to eliminate the clogging that accompanies filtration by performing cleaning and firing, and to reuse the element repeatedly.

Features of ceramic filter

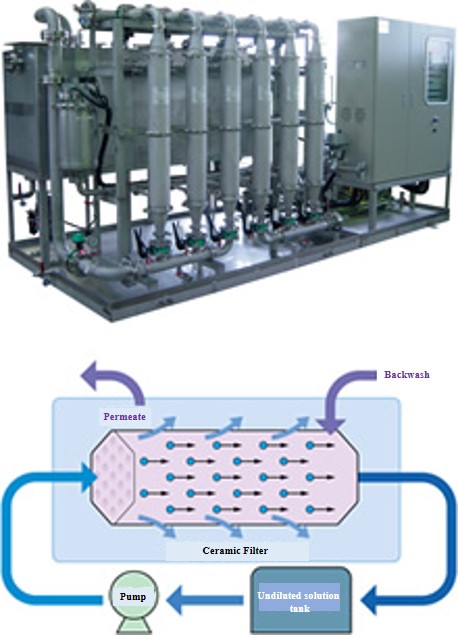

The ceramic filter uses cross-flow filtration, which constantly flushes the deposits on the filtration membrane while filtering, and is equipped with an automatic backwash / flushing mechanism to achieve more stable microfiltration.

Features

1. High filtration accuracy

Made of high-purity alumina ceramics, the pore distribution on the film surface is uniform, and high filtration accuracy can be obtained.

2. High corrosion resistance and heat resistance

Repeated chemical cleaning is possible. In addition, steam sterilization at about 120 ° C is possible.

3. High strength and wear resistance

Since it is excellent against internal pressure destruction, filtration of highly viscous liquid and slurry liquid is also effective.

4. Backwash reproducibility

Back pressure cleaning is possible, and a good and stable filtration flux can be obtained for a long time.

5. Abundant pore sizes

We have pore diameters from 5 nm to 1.4 μm, so you can select the membrane according to your application.

6. Maintenance free

It has excellent strength, corrosion resistance, abrasion resistance, and chemical resistance, and can build a maintenance-free system.

* We will also sell the element alone and return to cleaning. Please feel free to order.

Element type

Element dimensions

| Type | Dimensions | Pore diameter (unit) | Membrane material | Membrane shape | Membrane area (m2) |

Multi |

Opposite side 27 hexagon × 1020L |

MF 0.2/0.5/0.8/1.4(μm) |

α-Al2O3 |

4Φ x 19 holes | 0.24 |

| 3Φ x 37 holes | 0.35 | ||||

UF 20/50/100(nm) |

ZrO2 |

4Φ x 19 holes | 0.24 | ||

| 3Φ x 37 holes | 0.35 | ||||

| NF 10(nm) |

ZrO2 |

4Φ x 19 holes | 0.24 | ||

| 3Φ×37holes | 0.35 |

| Type | Dimensions | Pore diameter (unit) | Membrane material | Membrane shape | Membrane area (m2) |

Tube |

10φ×250L |

MF 0.2/0.5/0.8/1.4(μm) |

α-Al2O3 | 7Φ x 1 hole | 0.0055 |

| UF 20/50/100(nm) |

ZrO2 | 7Φ x 1 hole | 0.0055 | ||

| NF 10(nm) |

ZrO2 | 7Φ x 1 hole | 0.0055 |

※Element dimensions and hole diameter are subject to change.

Please contact us for details.

Example of using ceramic filter

For electronics and semiconductors

Wafer processing (BG, DC) Wastewater treatment

CMP wastewater treatment

Polishing of glass and lens, cutting wastewater treatment

Pretreatment of pure water equipment

For food

Refining, sterilization, and sterilization of soy sauce, sake, vinegar, etc.

Extraction from various solutions and broth (fractionation)

Sterilization of fragrance

Decontamination of prepared water

For chemistry

Concentrated recovery and purification of slurries and pastes

Separation and purification of polymers and monomers

Purification of chemicals

Removal of emulsion particles

Wafer

Waste oil / waste liquid regeneration

Automobile factory (regeneration of water-soluble coolant, regeneration of hydraulic oil / lubricating oil)

Bearing factory (regeneration of super finishing oil)

Various machining factories (regeneration of cleaning liquid, regeneration of hardened water) Desktop test machine

Desktop test machine

Research and Development / validation / small production

- Applicability to purification / concentration / clarification processes, etc.

- Verification of process improvement from distillation separation to membrane separation

- Replacement verification from organic membrane filter

- Validity evaluation for application development

- Challenge to new product development

- Small quantity production / sample production