Industrial Products Business

Noritake's Growth Strategy

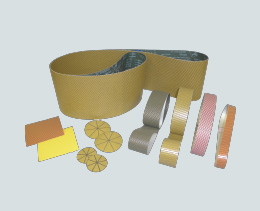

Main products

Grinding wheels, diamond wheels and tools, CBN wheels, cutting & offset wheels,coated abrasives, grinding & polishing-related products (grinding oil, etc.)

-

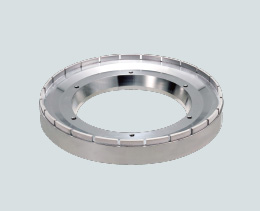

Multi-layer gear grinding wheel

"Gear Ace (Multi-Layer Type)" -

Metal wheels for high-efficiency, high-precision grinding "Ideal Metal (Wind chip)" -

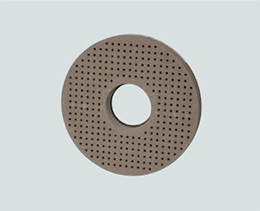

Grinding wheels for finishing SiC wafers -

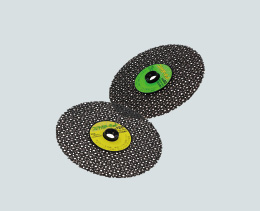

Disc Grinding Wheel "Flatdy" -

Glass cloth disk "Spider Net" -

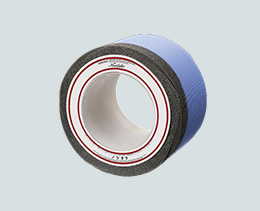

Diamond coated abrasive belt "Alta"

Performance in Fiscal 2023

In the custom-made products business, the semiconductor shortage in the Japanese automotive sector has gradually been resolved, leading to a recovery in production. However, production in the steel and bearings sectors has not yet recovered, leaving net sales at similar levels to the previous year. Overseas, automobile production increased compared to the previous year in North America, resulting in a high level of sales in the automotive parts and bearings sectors. In contrast, industrial machinery production in China declined due to the economic slowdown, and automobile production in Southeast Asia also decreased, leading to an overall drop in sales. In the general-purpose products business, sales of general-purpose grinding wheels, such as offset wheels, remained steady year-on-year, while sales of coated abrasives declined both in Japan and overseas. Regarding profits, we aggressively pursued efforts to improve revenue, including expanding sales, optimizing prices, and reducing costs. As a result, net sales in the industrial products business were 55.737 billion yen (a decrease of 3.0% from the previous year) while operating profit was 2.483 billion yen (an increase of 5.5% from the previous year).

Progress of the 12th Three-year Business Plan

In fiscal 2024, the final year of the Three-year Business Plan, we are accelerating efforts to enhance the revenue base of existing businesses and establish a foundation to advance into growth fields. Regarding market conditions, industries such as automotive, steel, bearings, and industrial machinery have been performing weaker than expected. Amid these circumstances, we are working to strengthen our revenue base by improving our production sites. In Japan, we have introduced the latest finishing machines at the Miyoshi Plant to automate and reduce manpower in the finishing process. At the same time, we are improving machining accuracy to strengthen the production system for products that can meet the growing demand for precision forms.

Overseas, we are reorganizing our products to capture the expanding market as the shift to electric vehicles (EVs) progresses. To optimize the production locations in Japan and overseas, NORITAKE SA (THAILAND) CO., LTD. (NSAT) has started manufacturing products previously produced at the Miyoshi and Yasu Plants and has started manufacturing products for NORITAKE U.S.A., INC. (NUSA) to improve profitability.

Growth Strategy

To enhance our presence in the growth areas of environment, electronics, and well-being, we are expanding the sales of various products: grinding wheels for EV gears in the environmental sector, grinding wheels for syringe needles in the well-being sector, grinding wheels for linear guide rails in the industrial machinery sector, and BG wheels and the LHA Pad® for semiconductor wafer grinding in the electronics sector.

Since fiscal 2023, the Kamori Plant has been updating its presses to expand the environment and well-being sectors. The Miyoshi Plant is formulating business concepts for new ventures and advancing the development of new products that support carbon neutrality, with the aim of introducing these products at the JIMTOF 2024 exhibition. In the electronics sector, we are expanding production capacity and investing in R&D, primarily for electronic and semiconductor-related products. In fiscal 2024, we will work together with equipment manufacturers to establish application technology for double-sided wafer polishing with the LHA Pad® and will also work to develop larger pads. We will continue to work with the Research & Development Center to expand our product lineup for semiconductors.

Additionally, to achieve our target of a 50% reduction in CO2 emissions by fiscal 2030 (compared to fiscal 2018), we will conduct tests in fiscal 2024 to switch gas furnaces to electric furnaces at the Miyoshi Plant with a focus on reducing CO2 emissions from city gas. The Miyoshi Plant will play a central role in studying tasks for the reduction of energy consumption for the future and will expand their measures to other plants.

MESSAGE

We are taking on the challenge of transformation to lead the industrial products business to the next generation.

Group General Manager of Industrial Products Group

Tomoaki Maeda

Amid significant changes in market conditions such as the electrification of automobiles, the industrial products business is sometimes perceived as an area with limited growth potential. However, I believe there is still room for significant growth in this sector. A forward-looking and proactive management strategy is critical for further growth. Since fiscal 2024, I have started visiting production and sales bases to engage in dialogue with employees. Through these conversations, I found that some employees are not familiar with the applications of the products they handle, or the end products involved, and have limited knowledge of the market. If we do not work on these issues, it will be difficult to foster a mindset of transformation to our employees or to expect innovation. Therefore, we will start with clarifying to the members of our group to understand what we manufacture at Japanese and overseas production sites, where these products are used, and how we will grow within that market. Looking ahead not 10 years, but 20 or 30 years and beyond, I urge all members of the Group to share a sense of urgency and take on the challenge of driving transformation with a sense of speed under the theme of "connecting our business to the next generation."