From Cutting to Grinding

Grinding Support

Safety

Miscellaneous Information

Information on fixed abrasives

- Catalog Download

- List of Catalog Download

- Grinding & Polishing Technical Information "NORITAKE TECHNICAL JOURNAL"

- About Our Sales Offices

From cutting to grinding. Noritake offers tools that can shorten the manufacturing process by replacing cutting processes with grinding processes, thus reducing manufacturing costs for customers.

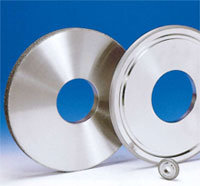

Electroplates Grinding Wheels

Electroplates wheels are used for grinding with only a single fixed layer of diamond or CBN deposited onto a core using electrolysis. They are ideal for a wide range of uses, from all types of ferrous materials to optics, electronic components and semiconductor materials. By using these wheels, customers can replace their blade-based cutting processes with grinding processes. Excellent finished surfaces can be obtained through high-efficiency machining and grinding.

Applications

Automobile engine valves, cam shafts and more

Grain Single Layered Metal Bonded CBN Wheel “Grit Ace”

Grit Ace employs grains arranged in an ordered pattern, and has a structure with core firmly bonded by brazing. It’s a new grinding wheel that maintains its original high-precision grinding and achieves highly efficient machining that rivals cutters.

Grit Ace can be used to replace milling cutter processes with grinding processes. Ground finished surfaces can be obtained with the same efficiency as cutting

Applications

Cylinder blocks made from materials like aluminum, aircraft parts made from CFRP (Carbon Fiber Reinforced Plastic) and more