Reduction of CO2 emissions and Waste

Sustainability Initiatives

- Sustainability at Noritake

- Contribute to the Global Environment

- Contribute to a Convenient Society

- Contribute to the People’s Well-being

- Strengthen the Foundation

- Management Structure

Initiatives to Reduce CO2 Emissions

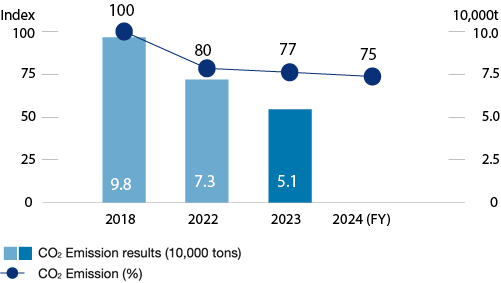

In order to transition to a low-carbon society and achieve net zero CO2 emissions, the Group has set long-term targets of reducing CO2 emissions (Scope1, 2) by 50% by FY2030 (compared to the FY2018 level) and achieving net zero emissions by FY2050. In order to reduce CO2 emissions toward achieving this target, we are actively promoting the utilization of renewable energy by adopting energy-saving facilities while working to increase productivity.

We also operate solar power generation facilities at seven domestic and three overseas business sites, making use of their premises in reducing annual CO2 emissions by 3,000 tons or more. We will continue to promote the introduction of solar power generation facilities in order to achieve net-zero CO2 emissions by 2050.

CO2 emissions results

In FY2023, the second year of our 12th Three-Year Environmental Action Plan, we achieved our target of reducing CO2 emissions by 48% compared to FY2018 through initiatives like introducing renewable energy and rationalizing production process.

CO2 Emission results (Scope1・2)

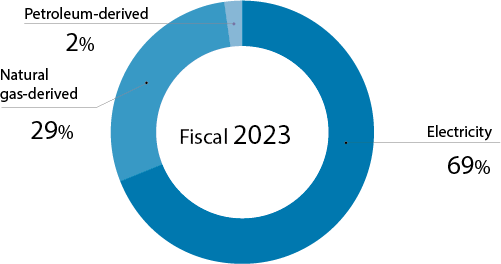

CO2 emissions ratio by energy type

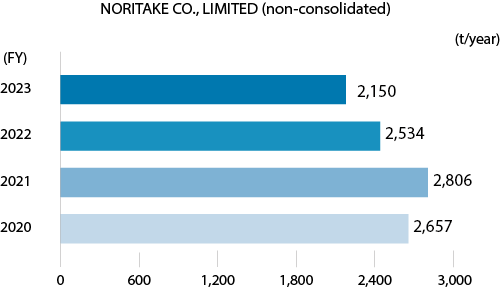

In addition, Noritake continuously monitors the amount of logistics transport in order to achieve efficient logistics. In fiscal 2023, our CO2 emissions were 2,150 tons with 12.08 million ton-kilometers of logistics transport.

CO2 emissions from logistics and transport

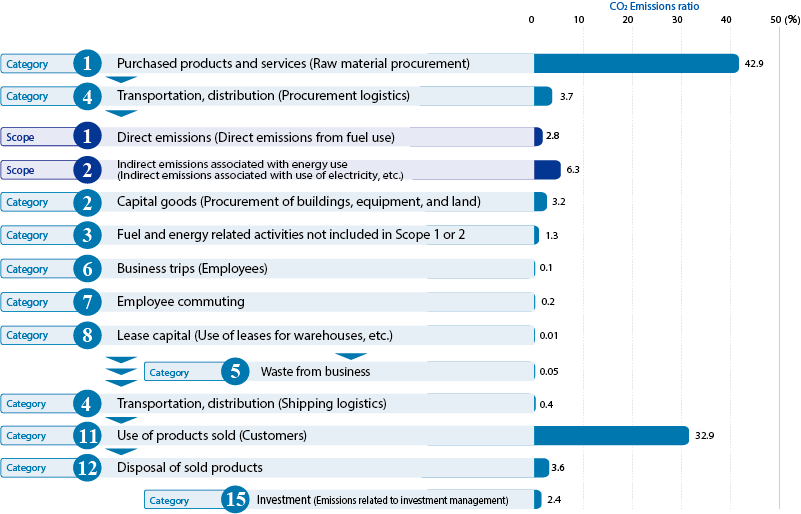

Overall picture of environmental burden

We are working to reduce environmental burden more effectively by monitoring the overall environmental burden of the entire product life cycle from raw material procurement to disposal after product use.

The Noritake Group calculates greenhouse gas emissions in line with international standards Scope 1 to 3, and uses them as an activity indicator.

* Calculation method

- ・Calculated in accordance with the Ministry of the Environment and Ministry of Economy, Trade and Industry's "Basic Guidelines on Accounting for Greenhouse Gas Emissions Throughout the Supply Chain Ver 2.0."

- ・Categories 9, 10, 13, and 14 out of the 15 categories of Scope 3 were excluded from the calculation because they are not applicable.

CO2 emissions throughout the supply chain

(Total of Scope 1 to 3)560 kilotons

Scope 1 : Direct company emissions

Scope 2: Indirect emissions associated with energy use (use of purchased electricity and heat)

Scope 3: Other indirect emissions (categories 1 to 8, 11, 12 and 15)

CO2 Emissions ratio

GX League

Established by the Ministry of Economy, Trade and Industry, the GX* League is a forum for cooperation between a group of like-minded companies and the government, universities, and academic institutions, in order to discuss reforms of the overall socioeconomic system and implement methods of generating new markets, toward achieving of carbon neutrality by 2050.

Noritake began supporting the GX League in May 2023.

※Green Transformation: A strategy of reforms for utilizing clean energy, and the activities required to achieve those reforms, while shifting away from excessive dependence on fossil fuels

Reducing waste

We understand that doing our utmost to reduce the generation of waste in our business activities is critical to making effective use of limited resources. At the Noritake Group, we undertake to reduce waste by quality improvement in conjunction with our manufacturing enhancement activities.

Noritake Recycling Center initiatives

Industrial grinding wheels are one of Noritake's core products, many of which are disposed of in landfills as industrial waste after use.

To address this, Noritake has been working on initiatives to effectively utilize and recycle these used grinding wheels.

The Noritake Recycle Center collects approximately 250 tons of used vitrified grinding wheels annually.

The collected grinding wheels are crushed, classified, and then reborn as products such as abrasive materials and heat-resistant materials.

Recycling process of used industrial grinding wheels

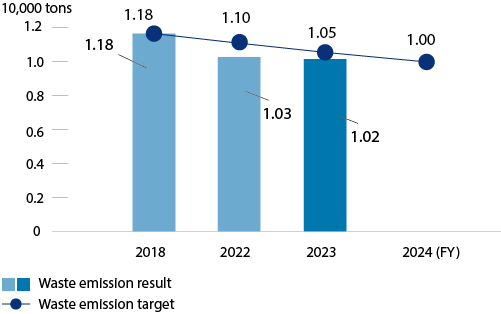

Waste emission result

In FY2023, the second year of our 12th Three-year Environmental Action Plan, we achieved an actual output of 10,200 tons with respect to the target of 10,500 tons or less waste emissions including at overseas sites.

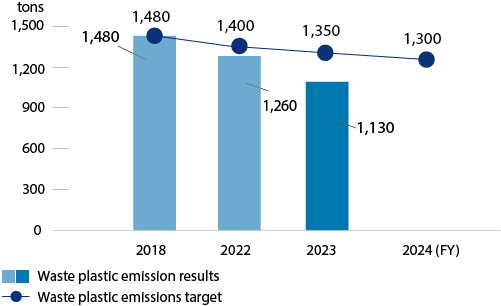

In Japan, we also achieved the target of 1,350 t of less waste plastic emissions, by achieving results of 1,130 t.

Waste emission result

Waste plastic emission results (Japan)