Grinding and Polishing Tools

-

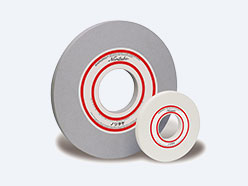

Grinding Wheels

Grinding Wheels

Tools for grinding, polishing and machining various materials.

- Vitrified

- Resinoid

Close

-

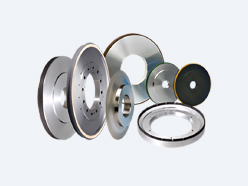

CBN Wheels

CBN Wheels

High-performance, long-life tools using CBN grain.

- CBN Wheels

-

- Crank Shaft Grinding CBN Wheel "Σ Wheel"

- New Porous CBN "FP Wheel"

- Multi-pore General-use CBN Wheel "KP-MEMOX"

- High-precision Flat Lapping CBN Wheel

- Super Long Life Vit-CBN Wheel "MEGA-LIFE WHEEL"

- Mirror-finish CBN Wheel

- Vitrified-bond CBN "Muscle Wheel"

- Centerless Vitrified-bond CBN/Diamond Wheel "Seamless Centerless Wheel"

- Internal Grinding CBN Wheel "XAP Wheel"

Close

-

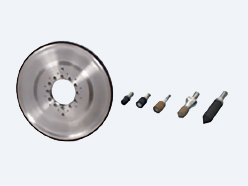

Diamond Tools

Diamond Tools

Tools for machining various non-ferrous materials using diamonds.

- Diamond Tools

-

- Beveling Wheel for Wafer

- Metal Wheel for Super-Hard Main Groove Grinding "Dress-less Metal (MDL)"

- Fixed Diamond Lapping Manufacture Metal Wheel

- Grain Single-layered Metal Bonded CBN Wheel "CBN Grit Ace"

- Honing Wheel Applicable to Water Soluble Coolant

- Grinding Wheel for Super-Hard Drill and Endmill Grinding "i-Flute"

- Cutting Tip Outer Edge Grinding Resin Wheel "i-Surface"

- Resin Bond Wheel for High Quality Profile Grinding "Keep Bright"

- Metal Bond Wheel for High Accuracy Profile Grinding "Keep Edge"

- General-use Multi-pore Diamond Grinding Wheel "SD MEMOX"

- Poreless Vitrified Diamond PCD Grinding Wheel "Smooth Fine"

- Surface Grinding Wheel for Silicon Ingots

- Porous Vitrified-bonded Diamond Wheel "VDH Wheel"

- Vitrified-bond Wheel for Cutting Tip Outer Edge Grinding "VTS Wheel"

- Mirror Finish Resinoid Wheel "Shine-G"

- Diamond dresser

Close

-

Coated Abrasive

Coated Abrasive

Grinding and polishing tools using grain-coated substrates such as paper and cloth.

- Coated Abrasive

Close

-

Coolants

Coolants

When grinding, polishing or cutting, Noritake’s coolants will draw out the machining performance of your tools.

- Coolants

Close

-

Related Products

Related Products

Noritake offers products for grinding and polishing.

- Related equipment

- Non-slip tape

- Other

Close

-

Grinding & Polishing

Ceramics & Materials

-

Electronic Paste (Thick Film)

-

Gypsum

-

Engineering Ceramics

-

Decoration Materials

-

Electronic Ceramic Powder

Electronic Ceramic Powder

Raw materials for use with pottery and glass or electronics field ceramics, etc.

- Electronic Ceramic Powder

Close

-

Vacuum Fluorescent Display

Vacuum Fluorescent Display

Displays such as vacuum fluorescent displays and digital signage.

- Vacuum Fluorescent Display

Close

-

Thick Film Circuit Substrate

Thick Film Circuit Substrate

Highly heat-tolerant circuit substrate made from a ceramic substrate.

- Thick Film Circuit Substrate

Close

Engineering

-

Heating Furnaces / Kilns

Heating Furnaces / Kilns

Heating systems and ancillary products for firing kilns and drying furnaces, etc.

- Heating Furnaces / Kilns

Close

-

Mixing Technology

Mixing Technology

Noritake provides actuator-less line mixers and related equipment.

- Mixing Technology

Close

-

Cutting Machine (Thin Cut Master : TCM)

Cutting Machine (Thin Cut Master : TCM)

Steel and automotive industry-centered machines for cutting and grinding.

- Cutting Machine (Thin Cut Master : TCM)

Close

-

Filtration Systems

Filtration Systems

Industrial filtration systems as well as filtration-related systems are available.

- Filtration Systems

Close