- HOME

- Product Information

- Engineering

- Mixing Technology

- SM Engineering Equipment

- Powder and Liquid Dispersion System

- Dispersion System "JSP Series"

Dispersion System "JSP Series"

Engineering

-

Heating Furnaces / Kilns

- Heating Furnaces / Kilns List

-

Drying Furnace

- Drying Furnace List

- Batch Kiln

- Far Infrared Conveyer Furnace

- Other Drying Furnaces

- Roll to Roll Far-infrared Heating Furnace

- Far Infrared Heater

-

Firing Kiln

- Firing Kiln List

- Roller Hearth Kiln

- Pusher Kiln

- Rotary Kiln

- Other

- Batch Kiln

- Refractory

-

Search by industry or usage

- Search by industry or usage List

- Semiconductors

- Energy

- Electronics

- Automobiles

- Displays and lighting

- Other

- Furnace Construction Maintenance

-

Mixing Technology

- Mixing Technology List

-

SM Engineering Equipment

- SM Engineering Equipment List

-

Heating and Cooling Systems

- Heating and Cooling Systems List

- Saccharification system for bio-ethanol production

- Adhesive Temperature Adjusting System

- Coating Liquid Precision Temperature (viscosity) Adjusting System

- Scrambled Eggs Continuation Manufacturing System

- Condiment Miso Heat Sterilization System

- Starch Gelatinization System for Paper Manufacturing

- Flour Paste Manufacturing System

- PVA Continuous Dissolution System

- Seasoning Liquid Heating Sterilization Cooling System

- Automated Oxidized Starch Production System

- In-line Starch Saccharification System

- Water Heating System

- Mixing Systems

- Powder and Liquid Dispersion System

- Reaction System

- Laboratory Test Systems

-

Heat Exchangers

- Heat Exchangers List

- Heat Exchangers

- Reaction

-

Static Mixer (SM)

- Static Mixer (SM) List

- Gas absorption(Option)

- Homogenization

- Miixing

- Option Parts

- Search by industry or usage

- Cooker / Steam Mixer

- Cutting Machine (Thin Cut Master : TCM)

-

Filtration Systems

- Filtration Systems List

- Search lubricants

-

Coolant Filtration Systems

- Coolant Filtration Systems List

- Centrifuge

- Coolant Tank Unit

- Magnetic Separator

- Cyclone Separator

- Paper Filter

- Backwash Filter

- Centralized Filtration Systems

- Search filtration materials

- Filtration Related Systems

- Ceramic filter

- Technical Support

- Catalog Download

- About Our Sales Offices

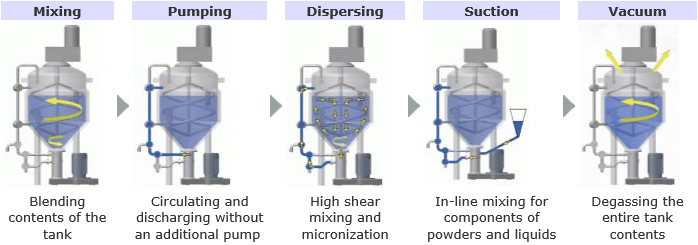

JSP is an all-in-one device, capable of mixing, dispersing, emulsification and wet grinding with this one unit. Technology developed in Germany has been reborn into this Japanese model. JSP units are hard at work in many industries including food, medicine, cosmetics and electronics.

Features

- 【Fully controllable degree of dispersion】

Control the particle size by changing the kinds of the generator or the speed of the disperser. - 【Inject raw material without opening the lid during the operation】

Powder or liquid is suctioned from the sub hopper directly into the disperser stage. This prevents clumping and facilitates density control. - 【Supports treatment for high viscosity liquid】

Maximum viscosity 100,000 mPa・s - 【Multi-function supporting assorted applications】

Supports heating and cooling of the chamber as well as vacuum degassing - 【Shortens the production time】

Combines mixer and disperser for efficient mixing and dispersing - 【Proposal for combination】

We can offer proposals for systems including processes before and after this unit incorporating many other kinds of machines such as static mixer.

Applications

[Food] Mayonnaise, Chocolate sauce, Peanut butter, Ketchup, Sauce, Dressing etc.

[Medicine/Cosmetics] Hair care supplies, Foundation, Lipstick, Toothpaste, Ointment, Eye drop etc.

[Electronics] LIB electrode slurry, Carbon slurry, Silver paste, Copper slurry, Nickle slurry, Insulating resin etc.

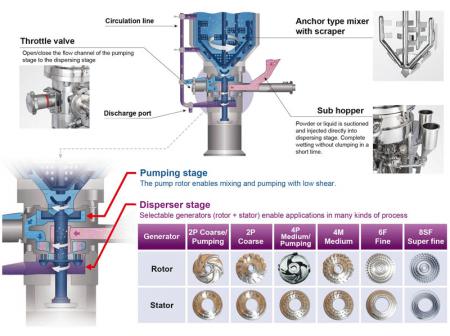

Structure

Specification

| Model | JSP25 | JSP50 | JSP100 | JSP250 | JSP500 | JSP1000 | |

|---|---|---|---|---|---|---|---|

| Tank Data |

Effective maximum treatment capacity |

25L | 50L | 100L | 200L | 500L | 1,000L |

| Effective minimum treatment capacity |

5L | 10L | 20L | 40L | 100L | 200L | |

| Tank total capacity | 32L | 65L | 130L | 260L | 650L | 1,350L | |

| Product Data |

Product pressure | Atmospheric pressure (Standard specification) -0.1MPa~ /(Optional pressurized tank) -0.1~0.25MPa |

|||||

| Product temperature |

-10~150℃ | ||||||

| Product viscosity | 1~100,000mPas | ||||||

| Anchored mixer |

Motor capacity | 1.5kW | 1.5kW | 2.2kW | 3.7kW | 5.5kW | 7.5kW |

| Shaft rotation speed | 225rpm | 165rpm | 135rpm | 110rpm | 81rpm | 65rpm | |

| Shaft seal | Radial shaft sealing (PTFE compounds) | ||||||

| Disperser DBI |

Model | 2000/04 | 2000/05 | 2000/10 | |||

| Motor capacity | 3.7kW | 7.5kW | 22kW | ||||

| Dispersing tools | Top: Pump rotor P / Bottom: Generator 4P | ||||||

| Shaft tool | Double mechanical seal (with sealing liquid pressurizing system) | ||||||

| Pumping stage max. flow (in case of water) |

6,000L/h | 15,000L/h | 40,000L/h | ||||

| Disperser stage max flow (in case of water) |

2,000L/h | 5,000L/h | 20,000L/h | ||||

| Other | Control | Touch panel | |||||

| Piping | ISO ferule | ||||||

| Wetted parts material | SUS316L / SUS316Ti / SUS304 | ||||||

| Standard equipment | Mixer scraper and baffle blade, DBI jacket, DBI supply hopper for additives etc. | ||||||

| Option | Tank temperature sensor, automatic valve, load cell, vacuum pump etc. | ||||||

*It can be designed to meet client’s requirement. Pleaser inquire for more details.

*Please feel free to contact us to see for yourself with our JSP25 trial unit.