- HOME

- Product Information

- Engineering

- Heating Furnaces / Kilns

- Firing Kiln

- Roller Hearth Kiln

- 2-Layer RHK for hot stamp

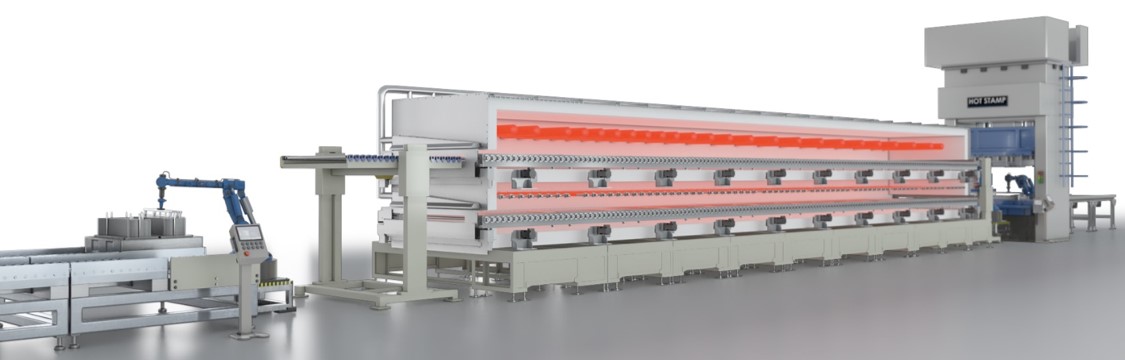

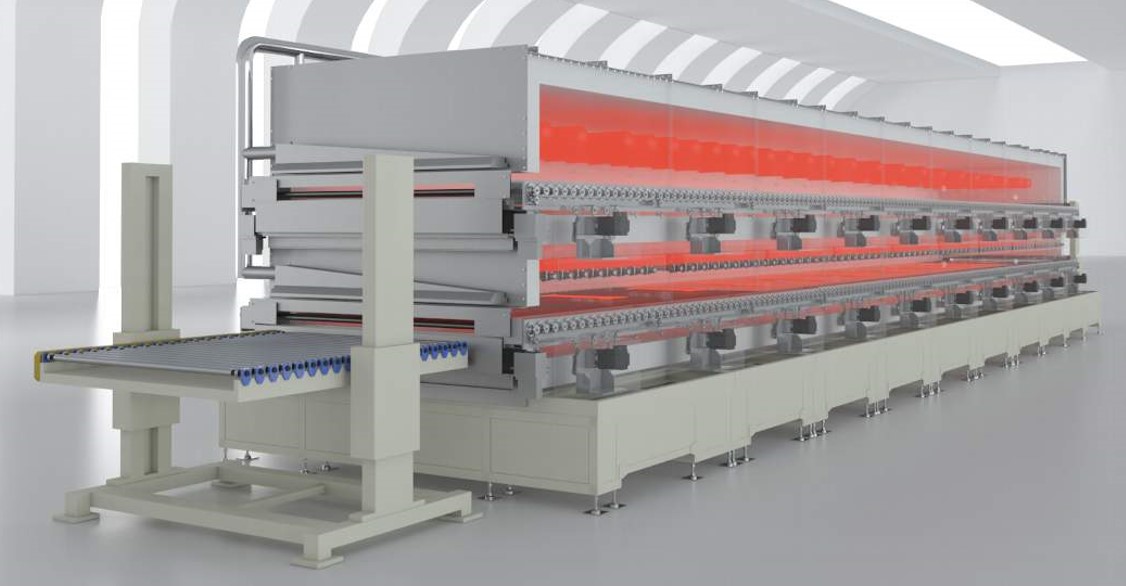

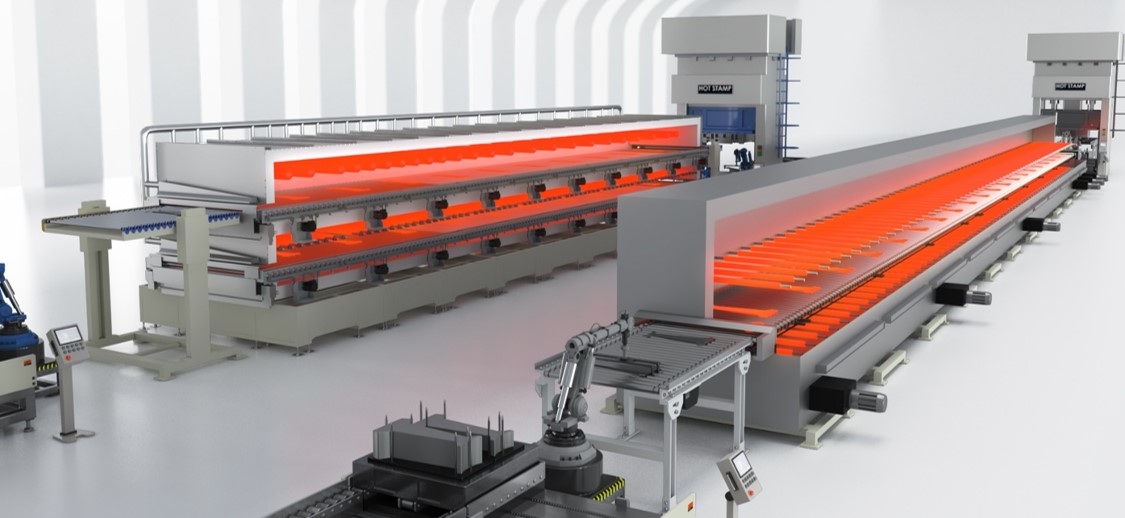

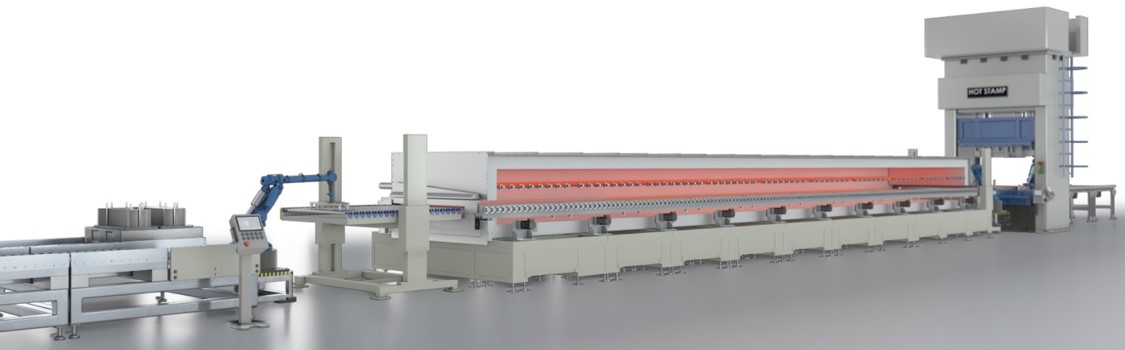

2-Layer RHK for hot stamp

Engineering

-

Heating Furnaces / Kilns

- Heating Furnaces / Kilns List

-

Drying Furnace

- Drying Furnace List

- Batch Kiln

- Far Infrared Conveyer Furnace

- Other Drying Furnaces

- Roll to Roll Far-infrared Heating Furnace

- Far Infrared Heater

-

Firing Kiln

- Firing Kiln List

- Roller Hearth Kiln

- Pusher Kiln

- Rotary Kiln

- Other

- Batch Kiln

- Refractory

-

Search by industry or usage

- Search by industry or usage List

- Semiconductors

- Energy

- Electronics

- Automobiles

- Displays and lighting

- Other

- Furnace Construction Maintenance

-

Mixing Technology

- Mixing Technology List

-

SM Engineering Equipment

- SM Engineering Equipment List

-

Heating and Cooling Systems

- Heating and Cooling Systems List

- Saccharification system for bio-ethanol production

- Adhesive Temperature Adjusting System

- Coating Liquid Precision Temperature (viscosity) Adjusting System

- Scrambled Eggs Continuation Manufacturing System

- Condiment Miso Heat Sterilization System

- Starch Gelatinization System for Paper Manufacturing

- Flour Paste Manufacturing System

- PVA Continuous Dissolution System

- Seasoning Liquid Heating Sterilization Cooling System

- Automated Oxidized Starch Production System

- In-line Starch Saccharification System

- Water Heating System

- Mixing Systems

- Powder and Liquid Dispersion System

- Reaction System

- Laboratory Test Systems

-

Heat Exchangers

- Heat Exchangers List

- Heat Exchangers

- Reaction

-

Static Mixer (SM)

- Static Mixer (SM) List

- Gas absorption(Option)

- Homogenization

- Miixing

- Option Parts

- Search by industry or usage

- Cooker / Steam Mixer

- Cutting Machine (Thin Cut Master : TCM)

-

Filtration Systems

- Filtration Systems List

- Search lubricants

-

Coolant Filtration Systems

- Coolant Filtration Systems List

- Centrifuge

- Coolant Tank Unit

- Magnetic Separator

- Cyclone Separator

- Paper Filter

- Backwash Filter

- Centralized Filtration Systems

- Search filtration materials

- Filtration Related Systems

- Ceramic filter

- Technical Support

- Catalog Download

- About Our Sales Offices

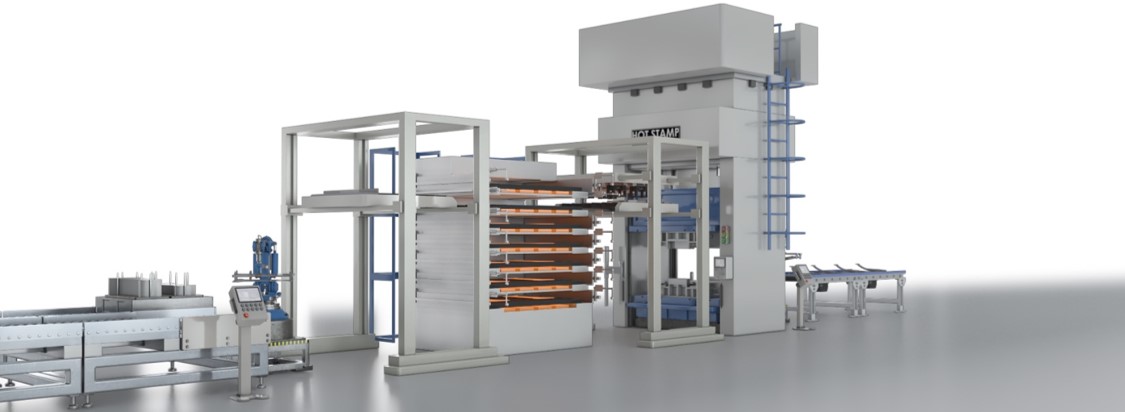

Hot stamp is a process that transmutes from automobile frame parts into high tensile force steel plates, improving collision safety performance and fuel reduction by reducing the weights.

Feature of Noritake 2-Layer RHK

- Energy saving, CO2 reduction.

・Energy cost 15% reduction.(Compared to our company)

・Consumable supplies cost 40% reduction.(Compared to our company) - Space-saving

・Heating kiln Installation area 45% reduction.(Compared to our company)

・Line Installation area 40% reduction.(Compared to our company) - High operating rate

・Line operation rate 5% improvement.(Compared to our company)

・One-side stage operation accommodating JIT method is enabled.

Unique kiln structure

・Both the upper stage and lower stage can be operated for production.

・While one stage(upper stage) is operated, the other stage can be stopped (the heater is off).

・The most unique heating kiln, enabling to set the operating stages in accordance with production volume and maintenance status.

Compatibility with existing equipment

The joint method between the front and back of heating kiln; and the conveyer is the same as the existing equipment.

・Compatibility using the existing equipment is supported.

Hot stamp line of 2-Layer RHK can be upgraded by replacing the heating kiln section while the peripheral equipment remains unchanged.

Standard Specification

| SPM | : ~6SPM |

| Working Area | : Max1.7mL×2.1mW |

| Heating Temp. | : Up to1000℃ |

| Atmosphere | : ①N2Gas ②Dry Air |

| Weight Capacity | : Up to 4,600kg/hr |

| Discharge Speed | : Up to120m/min |

| Kiln Length | : 19.5m |

Other selection of hot stamp products.

RHK

2-Layer RHK

Multi-Layer BK