- HOME

- Product Information

- Engineering

- Mixing Technology

- SM Engineering Equipment

- Heating and Cooling Systems

- Automated Oxidized Starch Production System

PRODUCTS

Automated Oxidized Starch Production System

Engineering

-

Heating Furnaces / Kilns

- Heating Furnaces / Kilns List

-

Drying Furnace

- Drying Furnace List

- Batch Kiln

- Far Infrared Conveyer Furnace

- Other Drying Furnaces

- Roll to Roll Far-infrared Heating Furnace

- Far Infrared Heater

-

Firing Kiln

- Firing Kiln List

- Roller Hearth Kiln

- Pusher Kiln

- Rotary Kiln

- Other

- Batch Kiln

- Refractory

-

Search by industry or usage

- Search by industry or usage List

- Semiconductors

- Energy

- Electronics

- Automobiles

- Displays and lighting

- Other

- Furnace Construction Maintenance

-

Mixing Technology

- Mixing Technology List

-

SM Engineering Equipment

- SM Engineering Equipment List

-

Heating and Cooling Systems

- Heating and Cooling Systems List

- Saccharification system for bio-ethanol production

- Adhesive Temperature Adjusting System

- Coating Liquid Precision Temperature (viscosity) Adjusting System

- Scrambled Eggs Continuation Manufacturing System

- Condiment Miso Heat Sterilization System

- Starch Gelatinization System for Paper Manufacturing

- Flour Paste Manufacturing System

- PVA Continuous Dissolution System

- Seasoning Liquid Heating Sterilization Cooling System

- Automated Oxidized Starch Production System

- In-line Starch Saccharification System

- Water Heating System

- Mixing Systems

- Powder and Liquid Dispersion System

- Reaction System

- Laboratory Test Systems

-

Heat Exchangers

- Heat Exchangers List

- Heat Exchangers

- Reaction

-

Static Mixer (SM)

- Static Mixer (SM) List

- Gas absorption(Option)

- Homogenization

- Miixing

- Option Parts

- Search by industry or usage

- Cooker / Steam Mixer

- Cutting Machine (Thin Cut Master : TCM)

-

Filtration Systems

- Filtration Systems List

- Search lubricants

-

Coolant Filtration Systems

- Coolant Filtration Systems List

- Centrifuge

- Coolant Tank Unit

- Magnetic Separator

- Cyclone Separator

- Paper Filter

- Backwash Filter

- Centralized Filtration Systems

- Search filtration materials

- Filtration Related Systems

- Ceramic filter

- Technical Support

- Catalog Download

- About Our Sales Offices

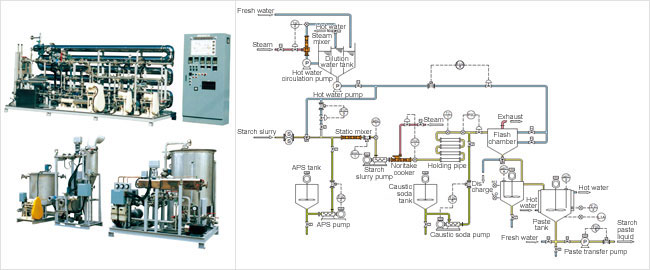

The automated oxidized starch production system adds an oxidizing agent to low-cost starch, and through thermo-chemical denaturation can perform automated continuous production of starch paste liquid equivalent to standard oxidized starch.

Advantages

- The system adds minute amounts of ammonium peroxodisulfate (APS) as an additive and mixes into a homogeneous starch slurry using a static mixer to perform precise denaturation preparation.

- The Noritake cooker provides excellent temperature uniformity even when heating starches like tapioca starch, which undergo sharp changes in viscosity.

- Caustic soda is uniformly supplied and mixed as a neutralizing agent with dilution water for concentration control, to produce starch paste liquid at the desired concentration, temperature, and pH.

- It can be equipped with an assortment of utility tanks, including liquid chemical tanks and water heating units for dilution.

Sample Specifications

| Processing capacity | Tapioca starch: 2.3 t/day (dry component equivalent) Input concentration: 35% Output concentration: 7 - 15% Gelatinization temperature: 150°C |

|---|---|

| Utilities | Steam: 690 kg/h (1.0 MPaG) Dilution water: 10 m³/h (0.2 MPaG) Air: 700 NL/min (0.5 MPaG) Electricity: 440V three-phase 12 kW |

| Dimensions and weight | Main Unit: 4,900 L × 1,700 W × 1,900 H (mm), approx. 2,000 kg Paste tank: 1,700 L × 1,700 W × 3,000 H (mm), approx. 300 kg NaOH tank: 1,000 L × 1,000 W × 1,200 H (mm), approx. 100 kg |