- HOME

- Product Information

- Engineering

- Mixing Technology

- SM Engineering Equipment

- Heating and Cooling Systems

- Condiment Miso Heat Sterilization System

PRODUCTS

Condiment Miso Heat Sterilization System

Engineering

-

Heating Furnaces / Kilns

- Heating Furnaces / Kilns List

-

Drying Furnace

- Drying Furnace List

- Batch Kiln

- Far Infrared Conveyer Furnace

- Other Drying Furnaces

- Roll to Roll Far-infrared Heating Furnace

- Far Infrared Heater

-

Firing Kiln

- Firing Kiln List

- Roller Hearth Kiln

- Pusher Kiln

- Rotary Kiln

- Other

- Batch Kiln

- Refractory

-

Search by industry or usage

- Search by industry or usage List

- Semiconductors

- Energy

- Electronics

- Automobiles

- Displays and lighting

- Other

- Furnace Construction Maintenance

-

Mixing Technology

- Mixing Technology List

-

SM Engineering Equipment

- SM Engineering Equipment List

-

Heating and Cooling Systems

- Heating and Cooling Systems List

- Saccharification system for bio-ethanol production

- Adhesive Temperature Adjusting System

- Coating Liquid Precision Temperature (viscosity) Adjusting System

- Scrambled Eggs Continuation Manufacturing System

- Condiment Miso Heat Sterilization System

- Starch Gelatinization System for Paper Manufacturing

- Flour Paste Manufacturing System

- PVA Continuous Dissolution System

- Seasoning Liquid Heating Sterilization Cooling System

- Automated Oxidized Starch Production System

- In-line Starch Saccharification System

- Water Heating System

- Mixing Systems

- Powder and Liquid Dispersion System

- Reaction System

- Laboratory Test Systems

-

Heat Exchangers

- Heat Exchangers List

- Heat Exchangers

- Reaction

-

Static Mixer (SM)

- Static Mixer (SM) List

- Gas absorption(Option)

- Homogenization

- Miixing

- Option Parts

- Search by industry or usage

- Cooker / Steam Mixer

- Cutting Machine (Thin Cut Master : TCM)

-

Filtration Systems

- Filtration Systems List

- Search lubricants

-

Coolant Filtration Systems

- Coolant Filtration Systems List

- Centrifuge

- Coolant Tank Unit

- Magnetic Separator

- Cyclone Separator

- Paper Filter

- Backwash Filter

- Centralized Filtration Systems

- Search filtration materials

- Filtration Related Systems

- Ceramic filter

- Technical Support

- Catalog Download

- About Our Sales Offices

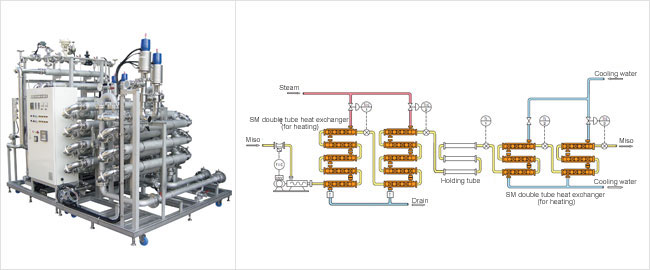

The sterilization system performs indirect heat sterilization and cooling of miso, sauces, and soups.

Advantages

- The system is equipped with CIP water-purifying functionality.

- Highly efficient heating and cooling is achieved using an SM double tube heat exchanger. It also incorporates an internal stirring mechanism which prevents burning.

- The flow channel is tubular, which allows uniform flow without backing up during operation unlike systems with plate heat exchangers.

Applications

- Heating, sterilizing, and cooling miso

- Heating, sterilizing, and cooling sauces and soups

Sample Specifications

| Processing capacity | Condiment miso: 1,000 kg/h Input temperature: 20°C Heating temperature: 125°C Cooling temperature: 60°C |

|---|---|

| Utilities | Steam: 220 kg/h (0.5 MPaG) Cooling water: 20 m³/h (35°C) Air: 700 NL/min (0.5 MPaG) Electricity: 200 V three-phase 2 kW |

| Dimensions and weight | 3450L×2000W×2150H (mm) Approx. 2,700 kg |