- HOME

- Product Information

- Engineering

- Heating Furnaces / Kilns

- Refractory

- Sagger / Plate

PRODUCTS

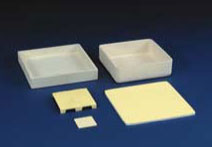

Sagger / Plate

Engineering

-

Heating Furnaces / Kilns

- Heating Furnaces / Kilns List

-

Drying Furnace

- Drying Furnace List

- Batch Kiln

- Far Infrared Conveyer Furnace

- Other Drying Furnaces

- Roll to Roll Far-infrared Heating Furnace

- Far Infrared Heater

-

Firing Kiln

- Firing Kiln List

- Roller Hearth Kiln

- Pusher Kiln

- Rotary Kiln

- Other

- Batch Kiln

- Refractory

-

Search by industry or usage

- Search by industry or usage List

- Semiconductors

- Energy

- Electronics

- Automobiles

- Displays and lighting

- Other

- Furnace Construction Maintenance

-

Mixing Technology

- Mixing Technology List

-

SM Engineering Equipment

- SM Engineering Equipment List

-

Heating and Cooling Systems

- Heating and Cooling Systems List

- Saccharification system for bio-ethanol production

- Adhesive Temperature Adjusting System

- Coating Liquid Precision Temperature (viscosity) Adjusting System

- Scrambled Eggs Continuation Manufacturing System

- Condiment Miso Heat Sterilization System

- Starch Gelatinization System for Paper Manufacturing

- Flour Paste Manufacturing System

- PVA Continuous Dissolution System

- Seasoning Liquid Heating Sterilization Cooling System

- Automated Oxidized Starch Production System

- In-line Starch Saccharification System

- Water Heating System

- Mixing Systems

- Powder and Liquid Dispersion System

- Reaction System

- Laboratory Test Systems

-

Heat Exchangers

- Heat Exchangers List

- Heat Exchangers

- Reaction

-

Static Mixer (SM)

- Static Mixer (SM) List

- Gas absorption(Option)

- Homogenization

- Miixing

- Option Parts

- Search by industry or usage

- Cooker / Steam Mixer

- Cutting Machine (Thin Cut Master : TCM)

-

Filtration Systems

- Filtration Systems List

- Search lubricants

-

Coolant Filtration Systems

- Coolant Filtration Systems List

- Centrifuge

- Coolant Tank Unit

- Magnetic Separator

- Cyclone Separator

- Paper Filter

- Backwash Filter

- Centralized Filtration Systems

- Search filtration materials

- Filtration Related Systems

- Ceramic filter

- Technical Support

- Catalog Download

- About Our Sales Offices

Total support

One of our strengths is the wide range of knowledge in firing processes, which enables us to offer reliable products.

Rich variety

We offer the best material, size and shape along with specialized processing to meet our customer's demands.

Mullite・Cordierite

It has high thermal-shock property, which allows high speed firing and rapid cooling. It offers high purity and porosity, and is capable of dealing with special shapes.

Alumina

The high heat resistance characteristic makes operations in high temperature zones possible. The high bending strength is also suitable for stacking. We have extensive lineup of alumina which enables us to offer you various options

Magnesia・Zirconia

The most heat-resistant products. It has high anti-reactivity against alkaline products, offering a long operating lifetime.

SiC

Great heat-conductivity corresponds to rapid heating/cooling of products. The great bending strength is suitable for high-loading products.Product Properties

Mullite・Cordierite

| Porosity (%) |

Bulk Density (g/cm3) |

Bending Strength (MPa) |

Thermal Expansion(%) at 1000°C |

Thermal Conductivity (W/mK) |

Chemical Components(%) |

Max. working Temperature (°C) |

||||

|---|---|---|---|---|---|---|---|---|---|---|

| Al2O3 | SiO2 | MgO | ||||||||

| KR-4A | Sagger, Plate | 29 | 2.1 | 9 | 0.30 | 0.9 | 57.3 | 32.6 | 8.3 | 1200°C |

| ANC | Sagger, Plate | 35 | 1.9 | 13 | 0.23 | 1.2 | 53.9 | 37.0 | 5.6 | 1200°C |

| MT-70 | Plate | 30 | 2.1 | 6 | 0.32 | 0.9 | 60.0 | 35.0 | 3.0 | 1200°C |

Mullite

| Porosity (%) |

Bulk Density (g/cm3) |

Bending Strength (MPa) |

Thermal Expansion(%) at 1000°C |

Thermal Conductivity (W/mK) |

Chemical Components(%) |

Max. working Temperature (°C) |

||||

|---|---|---|---|---|---|---|---|---|---|---|

| Al2O3 | SiO2 | MgO | ||||||||

| NR-H | Sagger, Plate | 24 | 2.3 | 11 | 0.36 | 1.8 | 65.0 | 35.0 | - | 1200°C |

| P1 | Plate | 71 | 1.1 | 10 | 0.77 | 0.6 | 84.0 | 16 | - | 1200°C |

Alumina

| Porosity (%) |

Bulk Density (g/cm3) |

Bending Strength (MPa) |

Thermal Expansion(%) at 1000°C |

Thermal Conductivity (W/mK) |

Chemical Components(%) |

Max. working Temperature (°C) |

||||

|---|---|---|---|---|---|---|---|---|---|---|

| Al2O3 | SiO2 | MgO | ||||||||

| MY-99X | Sagger, Plate | <0.1 | 3.9 | 300 | 0.80 | 31 | 99.7 | - | - | 1600°C |

| MM-8 | Sagger, Plate | 20 | 3.2 | 25 | 0.83 | 2.9 | 99.8 | - | - | 1600°C |

| MM-3 | Plate | 25 | 2.8 | 20 | 0.58 | 2.6 | 91.1 | 8.8 | - | 1500°C |

Spinel・Cordierite

| Porosity (%) |

Bulk Density (g/cm3) |

Bending Strength (MPa) |

Thermal Expansion(%) at 1000°C |

Thermal Conductivity (W/mK) |

Chemical Components(%) |

Max. working Temperature (°C) |

||||

|---|---|---|---|---|---|---|---|---|---|---|

| Al2O3 | SiO2 | MgO | ||||||||

| MK-3AM | Sagger, Plate | 35 | 2.0 | 8 | 0.29 | 1.4 | 57.4 | 19.2 | 19.8 | 1200°C |

| MK-7-3 | Sagger, Plate | 25 | 2.6 | 6 | 0.75 | 1.5 | 69.9 | 4.5 | 24.8 | 1200°C |

Magnesia

| Porosity (%) |

Bulk Density (g/cm3) |

Bending Strength (MPa) |

Thermal Expansion(%) at 1000°C |

Thermal Conductivity (W/mK) |

Chemical Components(%) |

Max. working Temperature (°C) |

||||

|---|---|---|---|---|---|---|---|---|---|---|

| Al2O3 | SiO2 | MgO | ||||||||

| MY-PS | Sagger, Plate | <0.1 | 3.2 | 100 | 1.30 | 15 | 0.4 | 0.4 | 98.5 | 1600°C |

| MY-M99 | Sagger, Plate | 17 | 3.0 | 13 | 1.30 | 3.9 | 0.2 | 0.3 | 98.8 | 1600°C |

Zirconia

| Porosity (%) |

Bulk Density (g/cm3) |

Bending Strength (MPa) |

Thermal Expansion(%) at 1000°C |

Thermal Conductivity (W/mK) |

Chemical Components(%) |

Max. working Temperature (°C) |

||||

|---|---|---|---|---|---|---|---|---|---|---|

| Al2O3 | SiO2 | MgO | ||||||||

| TZ-Y | Plate | <0.1 | 5.6 | 200 | 1.00 | 3.0 | ZrO2+Y2O3=99.8% | 1750°C | ||

| MY-Z42 | Sagger, Plate | 20 | 4.5 | 15 | 0.58 | 0.8 | ZrO2+CaO=99.0% | 1750°C | ||

SiC

| Porosity (%) |

Bulk Density (g/cm3) |

Bending Strength (MPa) |

Thermal Expansion(%) at 1000°C |

Thermal Conductivity (W/mK) |

Chemical Components(%) |

Max. working Temperature (°C) |

||||

|---|---|---|---|---|---|---|---|---|---|---|

| Al2O3 | SiO2 | MgO | ||||||||

| HE-902 | Plate | <0.1 | 3.1 | 450 | 0.44 | 180 | SiC=98.0% | 1450°C | ||

| KM-8 | Sagger, Plate | 23 | 2.4 | 79 | 0.43 | 154 | SiC=99% | 1350°C | ||

Carbon

| Porosity (%) |

Bulk Density (g/cm3) |

Bending Strength (MPa) |

Thermal Expansion(%) at 1000°C |

Thermal Conductivity (W/mK) |

Chemical Components(%) |

Max. working Temperature (°C) |

||||

|---|---|---|---|---|---|---|---|---|---|---|

| Al2O3 | SiO2 | MgO | ||||||||

| MY-C1 | Sagger, Plate | 15 | 1.7 | 14 | 0.3 | 150 | C=99.0% | - | ||

*Maximum working temperature depends on the processing objects and conditions.

(Grades other than listed above are also available.)