- HOME

- Product Information

- Engineering

- Heating Furnaces / Kilns

- Drying Furnace

- Roll to Roll Far-infrared Heating Furnace

- Roll to Roll Heating Furnace

Roll to Roll Heating Furnace

Engineering

-

Heating Furnaces / Kilns

- Heating Furnaces / Kilns List

-

Drying Furnace

- Drying Furnace List

- Batch Kiln

- Far Infrared Conveyer Furnace

- Other Drying Furnaces

- Roll to Roll Far-infrared Heating Furnace

- Far Infrared Heater

-

Firing Kiln

- Firing Kiln List

- Roller Hearth Kiln

- Pusher Kiln

- Rotary Kiln

- Other

- Batch Kiln

- Refractory

-

Search by industry or usage

- Search by industry or usage List

- Semiconductors

- Energy

- Electronics

- Automobiles

- Displays and lighting

- Other

- Furnace Construction Maintenance

-

Mixing Technology

- Mixing Technology List

-

SM Engineering Equipment

- SM Engineering Equipment List

-

Heating and Cooling Systems

- Heating and Cooling Systems List

- Saccharification system for bio-ethanol production

- Adhesive Temperature Adjusting System

- Coating Liquid Precision Temperature (viscosity) Adjusting System

- Scrambled Eggs Continuation Manufacturing System

- Condiment Miso Heat Sterilization System

- Starch Gelatinization System for Paper Manufacturing

- Flour Paste Manufacturing System

- PVA Continuous Dissolution System

- Seasoning Liquid Heating Sterilization Cooling System

- Automated Oxidized Starch Production System

- In-line Starch Saccharification System

- Water Heating System

- Mixing Systems

- Powder and Liquid Dispersion System

- Reaction System

- Laboratory Test Systems

-

Heat Exchangers

- Heat Exchangers List

- Heat Exchangers

- Reaction

-

Static Mixer (SM)

- Static Mixer (SM) List

- Gas absorption(Option)

- Homogenization

- Miixing

- Option Parts

- Search by industry or usage

- Cooker / Steam Mixer

- Cutting Machine (Thin Cut Master : TCM)

-

Filtration Systems

- Filtration Systems List

- Search lubricants

-

Coolant Filtration Systems

- Coolant Filtration Systems List

- Centrifuge

- Coolant Tank Unit

- Magnetic Separator

- Cyclone Separator

- Paper Filter

- Backwash Filter

- Centralized Filtration Systems

- Search filtration materials

- Filtration Related Systems

- Ceramic filter

- Technical Support

- Catalog Download

- About Our Sales Offices

Technical Support

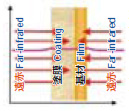

Infiltration of far-infrared ray reduces treating time significantly by heating the inside and outside of film simultaneously.

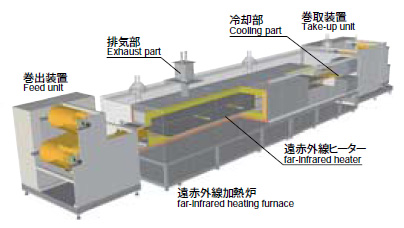

Cross section model of heat transferring (early stages of heating)

Hot-air heating method

Coating surface hardens first.

→ Internal solvent does not fall out.

→ Foaming and migration

Far-infrared heating method

Entire coating is dried efficiently and uniformly.

→ Shortening of processing time

→ Improvement in physical properties of a product

Features

Clean Heating

Low dust operation was realized by using Noritake Far Infrared Heater. Hot air through HEPA filters are used to improve the clean level of atmosphere to clean level 1000.

Reduced Heating Time

Considerable reduction of heating times is realized by a synergetic effect of zone-controlled radiation heating of far infrared and thermal diffusion by down blow.

Uniform Heating

Higher precision temperature profiles is realized by a combination of Far Infrared and clean hot air.

Energy Saving

Far infrared heating acts directly on the work exciting thermal motion increasing the temperature without heat loses which would otherwise be released into the heat transfer medium. Reduced heat loss to heat transfer medium and reduced heating time allow low running cost.

Systematization

Total systems including roll-in and roll-out equipment are available