- HOME

- Product Information

- Engineering

- Filtration Systems

- Coolant Filtration Systems

- Centrifuge

- Centri Clean EX NCX type

Centri Clean EX NCX type

Engineering

-

Heating Furnaces / Kilns

- Heating Furnaces / Kilns List

-

Drying Furnace

- Drying Furnace List

- Batch Kiln

- Far Infrared Conveyer Furnace

- Other Drying Furnaces

- Roll to Roll Far-infrared Heating Furnace

- Far Infrared Heater

-

Firing Kiln

- Firing Kiln List

- Roller Hearth Kiln

- Pusher Kiln

- Rotary Kiln

- Other

- Batch Kiln

- Refractory

-

Search by industry or usage

- Search by industry or usage List

- Semiconductors

- Energy

- Electronics

- Automobiles

- Displays and lighting

- Other

- Furnace Construction Maintenance

-

Mixing Technology

- Mixing Technology List

-

SM Engineering Equipment

- SM Engineering Equipment List

-

Heating and Cooling Systems

- Heating and Cooling Systems List

- Saccharification system for bio-ethanol production

- Adhesive Temperature Adjusting System

- Coating Liquid Precision Temperature (viscosity) Adjusting System

- Scrambled Eggs Continuation Manufacturing System

- Condiment Miso Heat Sterilization System

- Starch Gelatinization System for Paper Manufacturing

- Flour Paste Manufacturing System

- PVA Continuous Dissolution System

- Seasoning Liquid Heating Sterilization Cooling System

- Automated Oxidized Starch Production System

- In-line Starch Saccharification System

- Water Heating System

- Mixing Systems

- Powder and Liquid Dispersion System

- Reaction System

- Laboratory Test Systems

-

Heat Exchangers

- Heat Exchangers List

- Heat Exchangers

- Reaction

-

Static Mixer (SM)

- Static Mixer (SM) List

- Gas absorption(Option)

- Homogenization

- Miixing

- Option Parts

- Search by industry or usage

- Cooker / Steam Mixer

- Cutting Machine (Thin Cut Master : TCM)

-

Filtration Systems

- Filtration Systems List

- Search lubricants

-

Coolant Filtration Systems

- Coolant Filtration Systems List

- Centrifuge

- Coolant Tank Unit

- Magnetic Separator

- Cyclone Separator

- Paper Filter

- Backwash Filter

- Centralized Filtration Systems

- Search filtration materials

- Filtration Related Systems

- Ceramic filter

- Technical Support

- Catalog Download

- About Our Sales Offices

High precision separator with strong centrifugal force

Features

High Efficient Separating Filtration

High efficinet separating is provided by the powerful separating capacity, which is 4000rpm of max revolving speed and 3000G of max cenrigugal force.

Powerful Dehydrating Performance of Sludge

Sludge is recoverable with low water content through dewatering.

Automatic Operation

The autmatic drive covers the process of separating filtration, dehydration, sludge discharging and claening.

Bubble-less (Option) (Patent Pending)

The original bubble-less is installed as standard, and the problem of bubble is reduced.

Corrosion resistance

A high-precision type with stainless steel wetted perts has been added.

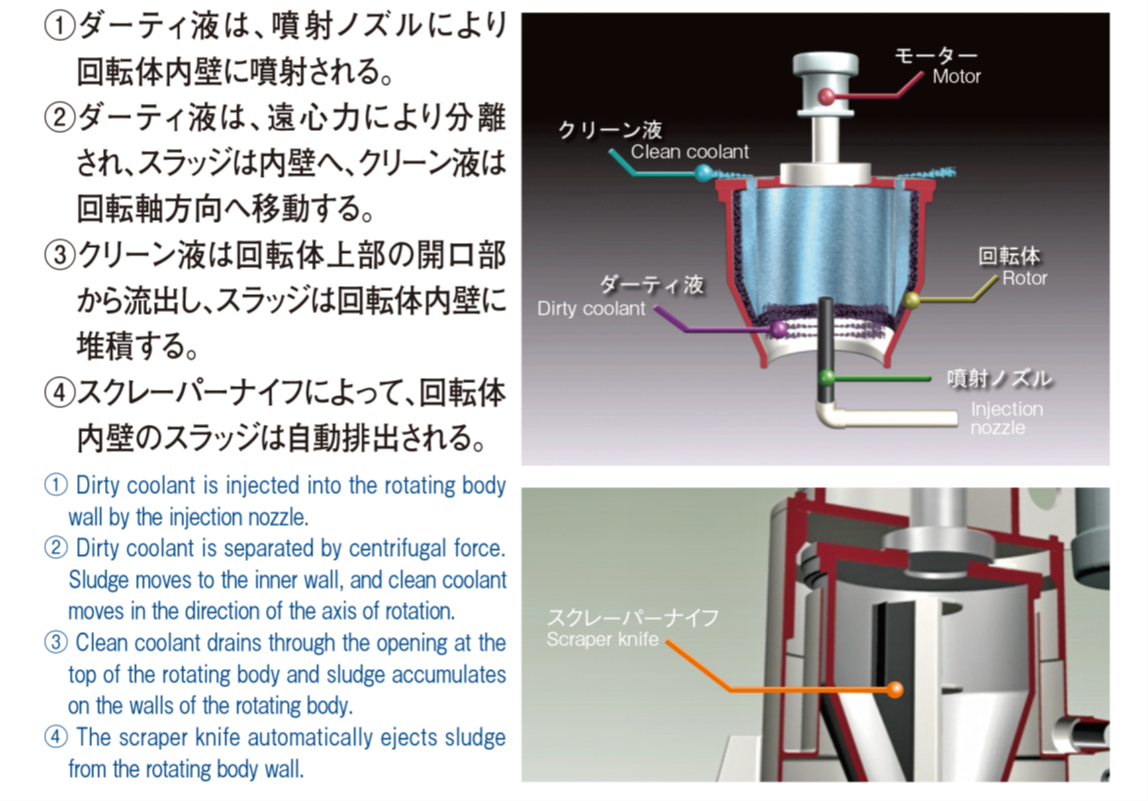

Principle

Application

Semiconductor material processing

Processing of semiconductor wafer materials such as Si and SiC, Each processing of LED substrates. Multislice wire saw , band saw etc

Wastewater treatment

Reduced load on comprehensive wastewater treatment equipment such as barrel wastewater and food wastewater.

Various machine tools

Purification and sludge collection of machining fluids for electric discharge machining, electrolytic polishing machines, honing machines, precision polishing machines, forgings / formers, etc.

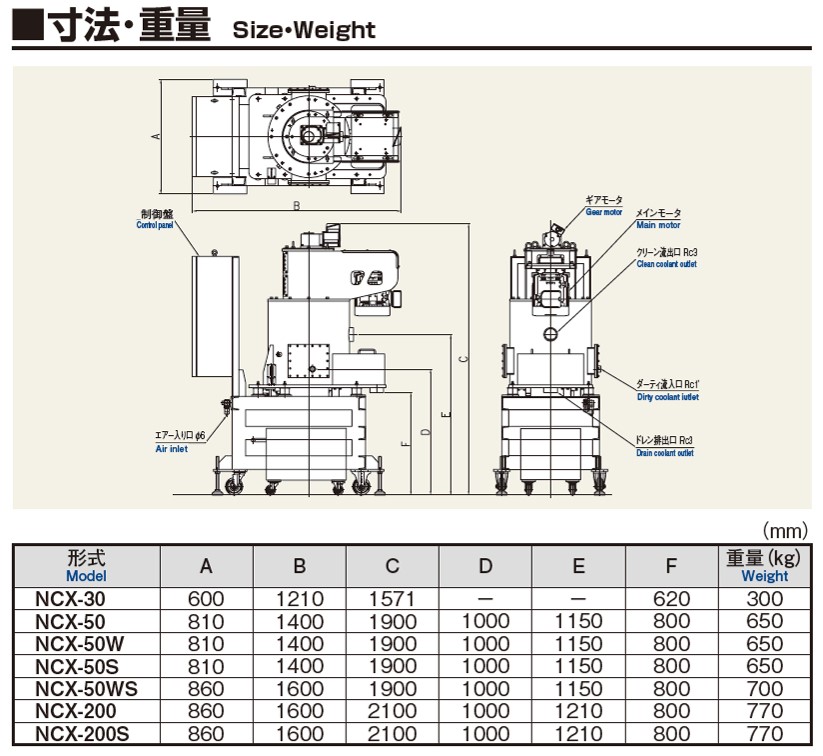

Size/Weight

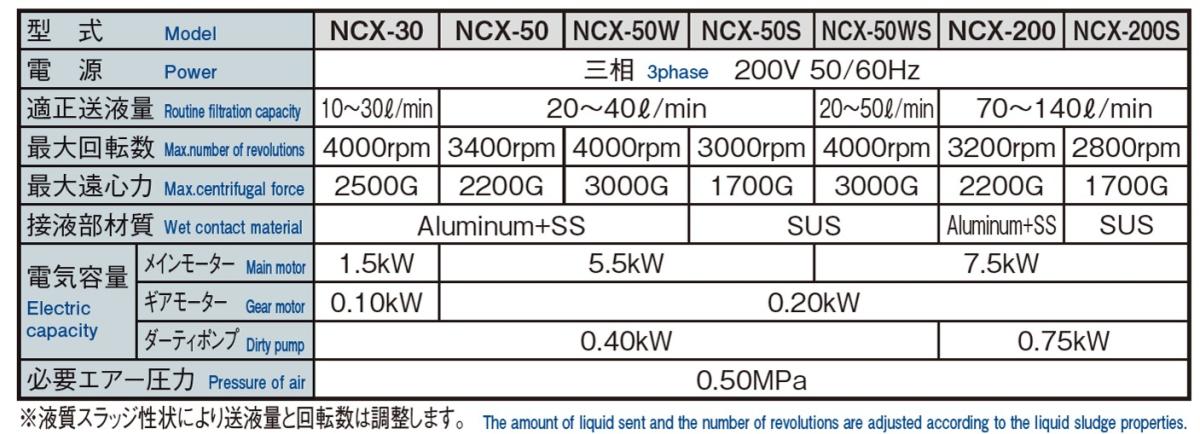

Specification

Performance

※Performance test condition

[Sample] Grinding sludge of glass (specific gravity2.5),

Average partcle diameter 2.3μm [Liquid] Water

| Sample | SS concentration | Extraction efficiency |

| Dirty liquid | 8461mg/L | ‐ |

| 1pass-clean liquid (NEW) | 2105mg/L | 75% |

| 1pass-clean liquid (Conventinal) | 3144mg/L | 63% |

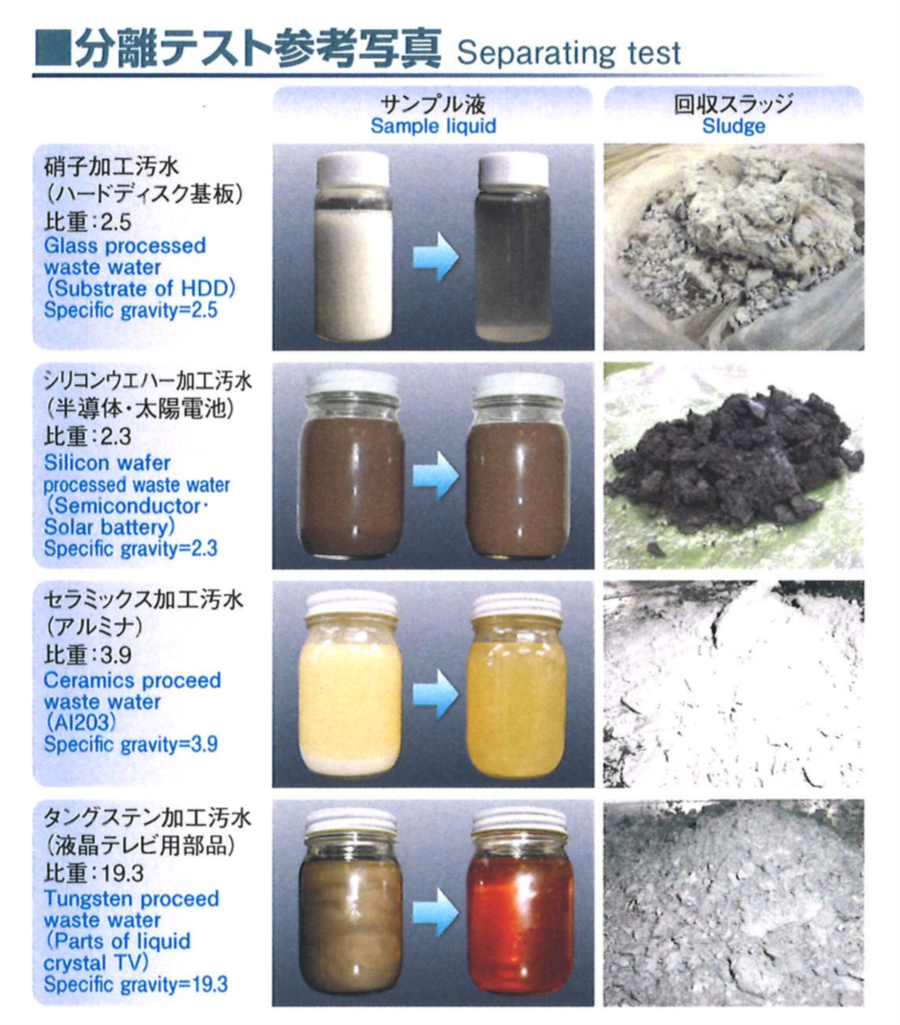

Separating test

Option

We have various options such as a Bubble-less mechanism and stainless steel specifications.

Please contact us.