PRODUCTS

Pusher Kiln

Engineering

-

Heating Furnaces / Kilns

- Heating Furnaces / Kilns List

-

Drying Furnace

- Drying Furnace List

- Batch Kiln

- Far Infrared Conveyer Furnace

- Other Drying Furnaces

- Roll to Roll Far-infrared Heating Furnace

- Far Infrared Heater

-

Firing Kiln

- Firing Kiln List

- Roller Hearth Kiln

- Pusher Kiln

- Rotary Kiln

- Other

- Batch Kiln

- Refractory

-

Search by industry or usage

- Search by industry or usage List

- Semiconductors

- Energy

- Electronics

- Automobiles

- Displays and lighting

- Other

- Furnace Construction Maintenance

-

Mixing Technology

- Mixing Technology List

-

SM Engineering Equipment

- SM Engineering Equipment List

-

Heating and Cooling Systems

- Heating and Cooling Systems List

- Saccharification system for bio-ethanol production

- Adhesive Temperature Adjusting System

- Coating Liquid Precision Temperature (viscosity) Adjusting System

- Scrambled Eggs Continuation Manufacturing System

- Condiment Miso Heat Sterilization System

- Starch Gelatinization System for Paper Manufacturing

- Flour Paste Manufacturing System

- PVA Continuous Dissolution System

- Seasoning Liquid Heating Sterilization Cooling System

- Automated Oxidized Starch Production System

- In-line Starch Saccharification System

- Water Heating System

- Mixing Systems

- Powder and Liquid Dispersion System

- Reaction System

- Laboratory Test Systems

-

Heat Exchangers

- Heat Exchangers List

- Heat Exchangers

- Reaction

-

Static Mixer (SM)

- Static Mixer (SM) List

- Gas absorption(Option)

- Homogenization

- Miixing

- Option Parts

- Search by industry or usage

- Cooker / Steam Mixer

- Cutting Machine (Thin Cut Master : TCM)

-

Filtration Systems

- Filtration Systems List

- Search lubricants

-

Coolant Filtration Systems

- Coolant Filtration Systems List

- Centrifuge

- Coolant Tank Unit

- Magnetic Separator

- Cyclone Separator

- Paper Filter

- Backwash Filter

- Centralized Filtration Systems

- Search filtration materials

- Filtration Related Systems

- Ceramic filter

- Technical Support

- Catalog Download

- About Our Sales Offices

Technical Support

Continuous firing furnace which conveys works on base plates using and oil pressure system.

Mass production for homogeneous works and stable operation under high temperature are ensured.

| Maximum temperature | 1600°C |

|---|---|

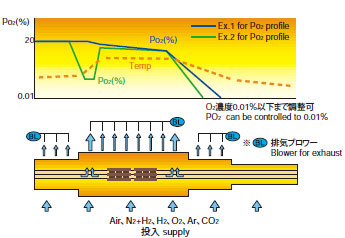

| Atmosphere | Air, N2, N2 + H2, H2, O2, Ar, CO2 |

| Heat source | Electricity |

Stable Transportation

-

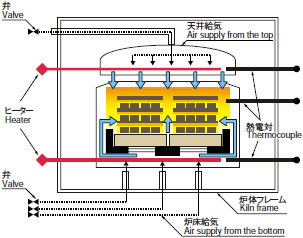

Our original design of the gas supply & exhaust holes allows for high precision atmosphere control possible. -

Air is supplied from both sides and center of the cross-section. Each valve can be individually adjusted, improving the atmosphere uniformity inside the kiln.

Layout example

Vacuum substitution system

N2consumption is reduced

Suitable to short cycle products. N2 consumption is reduced to Max.75%. (compared to our conventional model)

Insert Pusher

Stable Transportation

The practical pusher system for base plates has superior stability and reliability.

For precise control of transfer speed

Speed precision : Time difference ±1% (*Standard: ±2%)

High-temperature Continuous Firing

From de-binder temperature of 400°C to the firing temperature of over 1600°C , a wide range of heat treatment is available.