- HOME

- Product Information

- Engineering

- Heating Furnaces / Kilns

- Drying Furnace

- Far Infrared Conveyer Furnace

- Far-Infrared Annealing Furnace

PRODUCTS

Far-Infrared Annealing Furnace

Engineering

-

Heating Furnaces / Kilns

- Heating Furnaces / Kilns List

-

Drying Furnace

- Drying Furnace List

- Batch Kiln

- Far Infrared Conveyer Furnace

- Other Drying Furnaces

- Roll to Roll Far-infrared Heating Furnace

- Far Infrared Heater

-

Firing Kiln

- Firing Kiln List

- Roller Hearth Kiln

- Pusher Kiln

- Rotary Kiln

- Other

- Batch Kiln

- Refractory

-

Search by industry or usage

- Search by industry or usage List

- Semiconductors

- Energy

- Electronics

- Automobiles

- Displays and lighting

- Other

- Furnace Construction Maintenance

-

Mixing Technology

- Mixing Technology List

-

SM Engineering Equipment

- SM Engineering Equipment List

-

Heating and Cooling Systems

- Heating and Cooling Systems List

- Saccharification system for bio-ethanol production

- Adhesive Temperature Adjusting System

- Coating Liquid Precision Temperature (viscosity) Adjusting System

- Scrambled Eggs Continuation Manufacturing System

- Condiment Miso Heat Sterilization System

- Starch Gelatinization System for Paper Manufacturing

- Flour Paste Manufacturing System

- PVA Continuous Dissolution System

- Seasoning Liquid Heating Sterilization Cooling System

- Automated Oxidized Starch Production System

- In-line Starch Saccharification System

- Water Heating System

- Mixing Systems

- Powder and Liquid Dispersion System

- Reaction System

- Laboratory Test Systems

-

Heat Exchangers

- Heat Exchangers List

- Heat Exchangers

- Reaction

-

Static Mixer (SM)

- Static Mixer (SM) List

- Gas absorption(Option)

- Homogenization

- Miixing

- Option Parts

- Search by industry or usage

- Cooker / Steam Mixer

- Cutting Machine (Thin Cut Master : TCM)

-

Filtration Systems

- Filtration Systems List

- Search lubricants

-

Coolant Filtration Systems

- Coolant Filtration Systems List

- Centrifuge

- Coolant Tank Unit

- Magnetic Separator

- Cyclone Separator

- Paper Filter

- Backwash Filter

- Centralized Filtration Systems

- Search filtration materials

- Filtration Related Systems

- Ceramic filter

- Technical Support

- Catalog Download

- About Our Sales Offices

The significant reduction in annealing time by effectively using the heat emissions from far-infrared heaters revolutionizes the annealing of resin molds.

Temperatures Used: R.T. + 15 to 350°C

* Specified heater value

Temperature Accuracy: ±3°C

* Standard product temperature

Cleanliness: Class 10,000 (Class 1,000-compatible)

Sample Processed Products

-

「Automotive Parts」

Electronic sensors -

「Electronic Parts」

Electromagnetic switch -

「Precision Medical Instruments」

Dialysis parts

Features

- Significantly Shortened Processing Time

Significantly shortened processing time by combining far-infrared heat emission with heat dispersed by air blasting.

Conventional hot air batch furnace: 1-2 hours→Noritake Annealing Furnace: 3-5 minutes - Continuous Processing with Conveyor

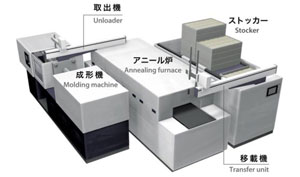

A compact continuous furnace is created by the shortened processing time. Therefore connection is possible with a molding machine to make one continuous process and increase production efficiency. - Better Quality

Heat uniformly by combining a highly responsive far-infrared heater with a hot air dryer. Furthermore, continuous processing makes for reliably accurate dimensions.

Dimension Accuracy:±5/100mm→±2/100mm

Sample Layout

Sample Annealing Processes

| Products | Materials | Size | Process | Heating Requirements | |

|---|---|---|---|---|---|

| Far-Infrared (Noritake) | Hot Air (Conventional) | ||||

| Electronic sensors | PBT (Polybutylene terephthalate) | 125×70×30 | Size stabilization | 140°C x 3 min. | 140°C x 2 h. |

| Electromagnetic switch | PA (Polyamide) | 50×50×60 | Size stabilization | 130°C x 10 min. | 130°C x 2 h. |

| Dialysis parts | PC (Polycarbonate) | φ60×280 | Distortion removal | 120°C x 3 min. | 120°C x 2 h. |

| Audio panel | PC (Polycarbonate) | 150×200×12 | Distortion removal | 120°C x 7 min. | 120°C x 2 h. |

| Plastic lens | Plastic | φ80×115 | Staining dry | 150°C x 30 min. | 150°C x 3 h. |

| Nut | PTFE (Polytetrafluoroethylene) | Φ10x5 | Size stabilization | 210°C x 20 min. | 210°C x 4 h. |

Specification Chart

| Standard Type | High Precision Type | |

|---|---|---|

| Device Name |

Far-Infrared Annealing Furnace (Standard Type) |

Far-Infrared Annealing Furnace (High Precision Type) |

| Device Model |

LF-AN2-*** | LF-HA2-*** |

| Method | Far-Infrared & Airblowing |

Far-Infrared & Propeller Air Dryer Circulator |

| Performance | ||

| Range of Used Temperatures |

R.T.+ 115-350°C * Heater Set Value | |

| Temperature Adjustment Accuracy |

±1°C (at 350°C) | |

| Temperature Distribution Accuracy |

±3°C | ±2°C |

| Far-Infrared Heater Zone Partitions |

3 zones x up/down = 6 zones | |

| Time to Stabilize Inside Furnace |

Approx. 60 min. | |

| Cleanliness | Class 10,000 (Class 1,000-compatible) | |

| Configuration | ||

| Interior | Stainless steel SUS304 | |

| Exterior | SS glazed coat | |

| Insulation | Rock wool | |

| Far-Infrared Heater |

Far-Infrared Ceramic Heater PLC-322 | |

| Hot Air Heater | Fin sheath heater (SUS) | |

| Fan | Air fan, Turbo fan | Circulation fan, Induction motor |

| Conveyor | Teflon mesh belt (glass fiber + Teflon coating) | |

| Conveyor Motor |

Induction motor with speed controller | |

| Controller | ||

| Temperature Control |

PID control via microcomputer inside thermometer | |

| Heater Control Circuit |

Zero-crossing SSR | |

| Conveyor Speed Control |

Managed via a speed controller | |

| Air Flow Control |

Damper | Invertor control |

| Safety Circuits |

Temperature abnormality, circuit breaker, conveyor abnormality, fan abnormality, emergency stop (control panel) | |

| Options | External input/output terminal, external communications adapter, recorder, power meter, 100 V outlet, entrance/exit emergency stop switch, neutralization unit, work backup detection sensor, area sensor, disconnection alarm, overheat alarm, open door alarm, touch screen control, stainless mesh belt | |

Dimensions / Power Consumption

| Model | Total Length (mm) |

Furnace Length (mm) |

Total Width (mm) |

Conveyor Working Width (mm) |

Device Height (mm) |

Path Line (mm) |

Electrical Capacity (KVA) |

|---|---|---|---|---|---|---|---|

| LF-AN2-104 | 2000 | 1000 | 850 | 400(350) | 1470 | 1150±25 | 14 |

| LF-AN2-154 | 2500 | 1500 | 850 | 400(350) | 1470 | 1150±25 | 21 |

| LF-AN2-157 | 2500 | 1500 | 1150 | 700(650) | 1470 | 1150±25 | 28 |

| LF-AN2-307 | 4000 | 3000 | 1150 | 700(650) | 1470 | 1150±25 | 52 |

| LF-HA2-154 | 2500 | 1500 | 850 | 400(350) | 1985 | 1150±25 | 25 |

| LF-HA2-157 | 2500 | 1500 | 1150 | 700(650) | 1985 | 1150±25 | 44 |

| LF-HA2-307 | 4000 | 3000 | 1150 | 700(650) | 1985 | 1150±25 | 58 |