- HOME

- Product Information

- Engineering

- Mixing Technology

- SM Engineering Equipment

- Heating and Cooling Systems

- Adhesive Temperature Adjusting System

PRODUCTS

Adhesive Temperature Adjusting System

Engineering

-

Heating Furnaces / Kilns

- Heating Furnaces / Kilns List

-

Drying Furnace

- Drying Furnace List

- Batch Kiln

- Far Infrared Conveyer Furnace

- Other Drying Furnaces

- Roll to Roll Far-infrared Heating Furnace

- Far Infrared Heater

-

Firing Kiln

- Firing Kiln List

- Roller Hearth Kiln

- Pusher Kiln

- Rotary Kiln

- Other

- Batch Kiln

- Refractory

-

Search by industry or usage

- Search by industry or usage List

- Semiconductors

- Energy

- Electronics

- Automobiles

- Displays and lighting

- Other

- Furnace Construction Maintenance

-

Mixing Technology

- Mixing Technology List

-

SM Engineering Equipment

- SM Engineering Equipment List

-

Heating and Cooling Systems

- Heating and Cooling Systems List

- Saccharification system for bio-ethanol production

- Adhesive Temperature Adjusting System

- Coating Liquid Precision Temperature (viscosity) Adjusting System

- Scrambled Eggs Continuation Manufacturing System

- Condiment Miso Heat Sterilization System

- Starch Gelatinization System for Paper Manufacturing

- Flour Paste Manufacturing System

- PVA Continuous Dissolution System

- Seasoning Liquid Heating Sterilization Cooling System

- Automated Oxidized Starch Production System

- In-line Starch Saccharification System

- Water Heating System

- Mixing Systems

- Powder and Liquid Dispersion System

- Reaction System

- Laboratory Test Systems

-

Heat Exchangers

- Heat Exchangers List

- Heat Exchangers

- Reaction

-

Static Mixer (SM)

- Static Mixer (SM) List

- Gas absorption(Option)

- Homogenization

- Miixing

- Option Parts

- Search by industry or usage

- Cooker / Steam Mixer

- Cutting Machine (Thin Cut Master : TCM)

-

Filtration Systems

- Filtration Systems List

- Search lubricants

-

Coolant Filtration Systems

- Coolant Filtration Systems List

- Centrifuge

- Coolant Tank Unit

- Magnetic Separator

- Cyclone Separator

- Paper Filter

- Backwash Filter

- Centralized Filtration Systems

- Search filtration materials

- Filtration Related Systems

- Ceramic filter

- Technical Support

- Catalog Download

- About Our Sales Offices

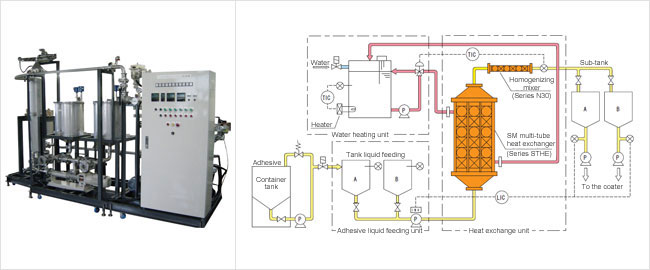

The adjustment system applies heat up to a set temperature to homogenize adhesive chemicals using a SM multi tube heat exchanger.

Advantages

- By using an SM heat exchanger, efficient heating of high-viscosity adhesives is possible without requiring much installation space.

- By using a static mixer installed at the heat exchanger output, temperature is stabilized and temperature accuracy improves.

- The water heating unit is attached in an all-in-one design.

- A steam or an electric heater can be selected as a heat source for heating water.

- Adhesive fluid flow rate can be automatically controlled according to the fluid level signal from the sub-tank in front of the coater.

- By using a temperature sensor at the static mixer output, the flow rate of hot water to the SM heat exchanger is controlled automatically, ensuring even greater adhesive temperature uniformity.

- We can also build an all-season model that includes a chiller unit, and can feed adhesive at a uniform temperature all year round by heating the adhesive in winter and cooling it in summer. This model allows the application of an adhesive coating that is always the same thickness.

Sample Specifications

| Processing capacity | Adhesive: 300–1,350 kg/h Temperature: 5–10°C (winter) → 25°C |

|---|---|

| Utilities | Electricity: 200V three-phase Hot water: 11,000 kg/h (30°C: winter) Air: 0.49 MPaG |

| Dimensions and weight | 3600L×1200W×2500H (mm) Approx. 1,500 kg |