- HOME

- Product Information

- Engineering

- Mixing Technology

- SM Engineering Equipment

- Heating and Cooling Systems

- Starch Gelatinization System for Paper Manufacturing

PRODUCTS

Starch Gelatinization System for Paper Manufacturing

Engineering

-

Heating Furnaces / Kilns

- Heating Furnaces / Kilns List

-

Drying Furnace

- Drying Furnace List

- Batch Kiln

- Far Infrared Conveyer Furnace

- Other Drying Furnaces

- Roll to Roll Far-infrared Heating Furnace

- Far Infrared Heater

-

Firing Kiln

- Firing Kiln List

- Roller Hearth Kiln

- Pusher Kiln

- Rotary Kiln

- Other

- Batch Kiln

- Refractory

-

Search by industry or usage

- Search by industry or usage List

- Semiconductors

- Energy

- Electronics

- Automobiles

- Displays and lighting

- Other

- Furnace Construction Maintenance

-

Mixing Technology

- Mixing Technology List

-

SM Engineering Equipment

- SM Engineering Equipment List

-

Heating and Cooling Systems

- Heating and Cooling Systems List

- Saccharification system for bio-ethanol production

- Adhesive Temperature Adjusting System

- Coating Liquid Precision Temperature (viscosity) Adjusting System

- Scrambled Eggs Continuation Manufacturing System

- Condiment Miso Heat Sterilization System

- Starch Gelatinization System for Paper Manufacturing

- Flour Paste Manufacturing System

- PVA Continuous Dissolution System

- Seasoning Liquid Heating Sterilization Cooling System

- Automated Oxidized Starch Production System

- In-line Starch Saccharification System

- Water Heating System

- Mixing Systems

- Powder and Liquid Dispersion System

- Reaction System

- Laboratory Test Systems

-

Heat Exchangers

- Heat Exchangers List

- Heat Exchangers

- Reaction

-

Static Mixer (SM)

- Static Mixer (SM) List

- Gas absorption(Option)

- Homogenization

- Miixing

- Option Parts

- Search by industry or usage

- Cooker / Steam Mixer

- Cutting Machine (Thin Cut Master : TCM)

-

Filtration Systems

- Filtration Systems List

- Search lubricants

-

Coolant Filtration Systems

- Coolant Filtration Systems List

- Centrifuge

- Coolant Tank Unit

- Magnetic Separator

- Cyclone Separator

- Paper Filter

- Backwash Filter

- Centralized Filtration Systems

- Search filtration materials

- Filtration Related Systems

- Ceramic filter

- Technical Support

- Catalog Download

- About Our Sales Offices

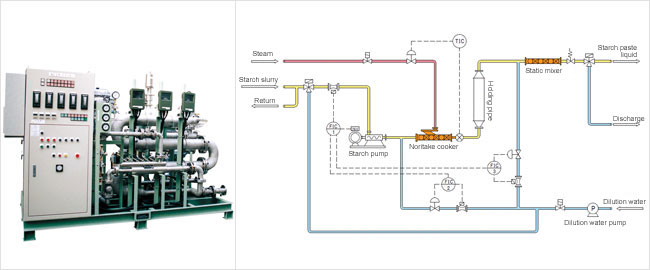

The paper system performs automated starch paste production with consistent density by using steam to directly heat and gelatinize starch slurry, and then diluting the starch paste liquid.

Fully Automatic Model

Advantages

- The system enables consistent gelatinization at both low and high concentrations regardless of the starch type, including corn and potato starch.

- The system can accommodate a wide range of load fluctuations and provides a continuous source of starch paste liquid of uniform quality.

- The system operates reliably with little pressure loss from the Noritake cooker in spite of relatively little steam.

- When operation is halted, the system automatically washes its internal components with hot water. (self-cleaning feature)

- Full automation of the system allows for easy operation.

- The system is compact and requires little installation space.

- The flow rates for the starch slurry, primary dilution water and secondary dilution water are digitally controlled. In addition, changes to dilution water flow rate can be done in real-time according to changes in starch slurry flow rate through the cascade control function.

- The system is equipped with a temperature control system that combines a Noritake cooker and its independent mixing functionality with control functions.

- As an option, the system can be linked with DCS.

Sample Specifications

| Processing capacity | Cationized starch: 12 t/day (solid component equivalent) Input concentration: 30% Output concentration: 1.5 - 2% Gelatinization temperature: 110°C |

|---|---|

| Utilities | Steam: 1,200 kg/h (1.03 MPaG) Dilution water: 35 m³/h (0.2 MPaG) Air: 400 NL/min (0.5 MPaG) Electricity: 200 V three-phase 6 kW |

| Dimensions and weight | 3000L×1800W×2300H (mm) Approx. 1,600 kg |

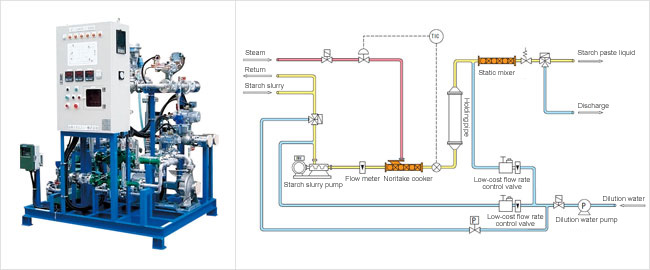

Semi-Automatic Model

Advantages

- This model offers excellent cost-performance.

- Its basic functionality, such as automatic operation and self-cleaning, is based directly on the fully automatic model.

- Starch slurry flow rate is controlled via the starch slurry pump inverter, and dilution water flow rate is controlled via a self-control valve.

Sample Specifications

| Processing capacity | Cationized starch: 4.3 t/day (solid component equivalent) Input concentration: 25% Output concentration: 1% Gelatinization temperature: 110°C |

|---|---|

| Utilities | Steam: 560 kg/h (0.5 MPaG) Dilution water: 20 m³/h (0.1 MPaG) Air: 400 NL/min (0.5 MPaG) Electricity: 200 V three-phase 5 kW |

| Dimensions and weight | 2050L×1300W×1950H (mm) Approx. 1200kg |