- HOME

- Product Information

- Engineering

- Mixing Technology

- SM Engineering Equipment

- Heating and Cooling Systems

- Coating Liquid Precision Temperature (viscosity) Adjusting System

PRODUCTS

Coating Liquid Precision Temperature (viscosity) Adjusting System

Engineering

-

Heating Furnaces / Kilns

- Heating Furnaces / Kilns List

-

Drying Furnace

- Drying Furnace List

- Batch Kiln

- Far Infrared Conveyer Furnace

- Other Drying Furnaces

- Roll to Roll Far-infrared Heating Furnace

- Far Infrared Heater

-

Firing Kiln

- Firing Kiln List

- Roller Hearth Kiln

- Pusher Kiln

- Rotary Kiln

- Other

- Batch Kiln

- Refractory

-

Search by industry or usage

- Search by industry or usage List

- Semiconductors

- Energy

- Electronics

- Automobiles

- Displays and lighting

- Other

- Furnace Construction Maintenance

-

Mixing Technology

- Mixing Technology List

-

SM Engineering Equipment

- SM Engineering Equipment List

-

Heating and Cooling Systems

- Heating and Cooling Systems List

- Saccharification system for bio-ethanol production

- Adhesive Temperature Adjusting System

- Coating Liquid Precision Temperature (viscosity) Adjusting System

- Scrambled Eggs Continuation Manufacturing System

- Condiment Miso Heat Sterilization System

- Starch Gelatinization System for Paper Manufacturing

- Flour Paste Manufacturing System

- PVA Continuous Dissolution System

- Seasoning Liquid Heating Sterilization Cooling System

- Automated Oxidized Starch Production System

- In-line Starch Saccharification System

- Water Heating System

- Mixing Systems

- Powder and Liquid Dispersion System

- Reaction System

- Laboratory Test Systems

-

Heat Exchangers

- Heat Exchangers List

- Heat Exchangers

- Reaction

-

Static Mixer (SM)

- Static Mixer (SM) List

- Gas absorption(Option)

- Homogenization

- Miixing

- Option Parts

- Search by industry or usage

- Cooker / Steam Mixer

- Cutting Machine (Thin Cut Master : TCM)

-

Filtration Systems

- Filtration Systems List

- Search lubricants

-

Coolant Filtration Systems

- Coolant Filtration Systems List

- Centrifuge

- Coolant Tank Unit

- Magnetic Separator

- Cyclone Separator

- Paper Filter

- Backwash Filter

- Centralized Filtration Systems

- Search filtration materials

- Filtration Related Systems

- Ceramic filter

- Technical Support

- Catalog Download

- About Our Sales Offices

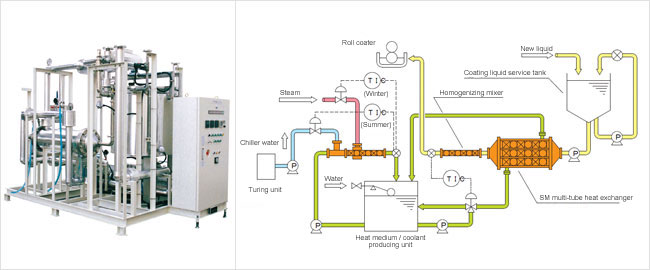

The system allows you to rapidly apply accurate heating and cooling to fluids for which heat management is important, using a highly efficient SM heat exchanger.

Advantages

- The system measures the original temperature of liquid coatings and automatically determines heating, cooling, and temperature maintenance according to the difference from the set temperature. The temperature of the heating medium (or coolant) is also automatically regulated. (Using a static mixer, the heating medium [hot water] is directly heated using steam, and the coolant is mixed with chiller water.)

- The increased viscosity of the coating liquid due to the reduction in the solvent amount is cancelled out by the decrease in viscosity due to heating, and therefore the quality of coated products can be maintained while reducing the amount of solvent used.

- It improves the work environment through reduced solvent usage, and can reduce the environmental impact of post-process drying machines.

- It ensures consistent viscosity by its ability to maintain stable coating liquid temperatures all year long (operating within ±1°C margins), thus making consistent coat thicknesses possible.

Sample Specifications

| Processing capacity | Coating liquid processing rate: 28L/min Viscosity: 500 cP Original temperature: 10 - 40°C Regulated temperature: 30 - 45°C |

|---|---|

| Utilities | Air: 0.49 MPaG Steam: 0.2 MPaG Chiller water: 10°C Electricity: 200V three-phase 20 kW |

| Dimensions and weight | 2200L×1500W×2200H (mm) Approx. 1,000 kg |