- HOME

- Product Information

- Engineering

- Mixing Technology

- SM Engineering Equipment

- Reaction System

- Continuous Polymerization Reaction System

PRODUCTS

Continuous Polymerization Reaction System

Engineering

-

Heating Furnaces / Kilns

- Heating Furnaces / Kilns List

-

Drying Furnace

- Drying Furnace List

- Batch Kiln

- Far Infrared Conveyer Furnace

- Other Drying Furnaces

- Roll to Roll Far-infrared Heating Furnace

- Far Infrared Heater

-

Firing Kiln

- Firing Kiln List

- Roller Hearth Kiln

- Pusher Kiln

- Rotary Kiln

- Other

- Batch Kiln

- Refractory

-

Search by industry or usage

- Search by industry or usage List

- Semiconductors

- Energy

- Electronics

- Automobiles

- Displays and lighting

- Other

- Furnace Construction Maintenance

-

Mixing Technology

- Mixing Technology List

-

SM Engineering Equipment

- SM Engineering Equipment List

-

Heating and Cooling Systems

- Heating and Cooling Systems List

- Saccharification system for bio-ethanol production

- Adhesive Temperature Adjusting System

- Coating Liquid Precision Temperature (viscosity) Adjusting System

- Scrambled Eggs Continuation Manufacturing System

- Condiment Miso Heat Sterilization System

- Starch Gelatinization System for Paper Manufacturing

- Flour Paste Manufacturing System

- PVA Continuous Dissolution System

- Seasoning Liquid Heating Sterilization Cooling System

- Automated Oxidized Starch Production System

- In-line Starch Saccharification System

- Water Heating System

- Mixing Systems

- Powder and Liquid Dispersion System

- Reaction System

- Laboratory Test Systems

-

Heat Exchangers

- Heat Exchangers List

- Heat Exchangers

- Reaction

-

Static Mixer (SM)

- Static Mixer (SM) List

- Gas absorption(Option)

- Homogenization

- Miixing

- Option Parts

- Search by industry or usage

- Cooker / Steam Mixer

- Cutting Machine (Thin Cut Master : TCM)

-

Filtration Systems

- Filtration Systems List

- Search lubricants

-

Coolant Filtration Systems

- Coolant Filtration Systems List

- Centrifuge

- Coolant Tank Unit

- Magnetic Separator

- Cyclone Separator

- Paper Filter

- Backwash Filter

- Centralized Filtration Systems

- Search filtration materials

- Filtration Related Systems

- Ceramic filter

- Technical Support

- Catalog Download

- About Our Sales Offices

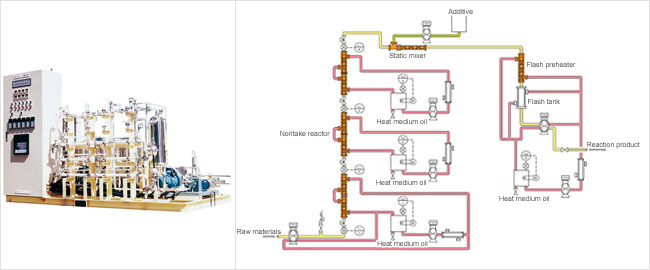

The Noritake polymerization reaction test machine was designed as a test machine that would allow static continuous block polymerization reactions. It is an ideal system for continuous polymerization reaction testing because the Noritake reactor is used on the cylindrical reaction chamber and the SM double tube heat exchanger is used on the flash preheater.

Advantages

- The polymerization reactor uses a double tube static mixer, allowing for piston flow in the reaction system flow, eliminating uneven pile-ups and obtaining reliable polymers.

- Using our own in-house flash preheater, we have succeeded in avoiding polymer deterioration (burning) of the transfer surface and reducing additives (such as bluing additives for color improvement).

- We’ve improved production reliability through reduced strand breakage and complete demonomerization.

Sample Specifications

| Processing capacity | Raw material flow volume: 1.0 L/h (100 – 150°C) Reaction product flow volume (intermittent): 3.5 L/h (100 – 200°C) Additive flow volume: 0.1 L/h (room temperature) Heat medium cycle volume: 100 L/h (50 – 250°C) |

|---|---|

| Utilities | Electricity: 200 V three-phase 4 kW |

| Dimensions and weight | 2900L×1400W×2000H (mm) Approx. 800 kg |