- HOME

- Product Information

- Engineering

- Mixing Technology

- SM Engineering Equipment

- Mixing Systems

- Coating Liquid Continuous Mixing System

PRODUCTS

Coating Liquid Continuous Mixing System

Engineering

-

Heating Furnaces / Kilns

- Heating Furnaces / Kilns List

-

Drying Furnace

- Drying Furnace List

- Batch Kiln

- Far Infrared Conveyer Furnace

- Other Drying Furnaces

- Roll to Roll Far-infrared Heating Furnace

- Far Infrared Heater

-

Firing Kiln

- Firing Kiln List

- Roller Hearth Kiln

- Pusher Kiln

- Rotary Kiln

- Other

- Batch Kiln

- Refractory

-

Search by industry or usage

- Search by industry or usage List

- Semiconductors

- Energy

- Electronics

- Automobiles

- Displays and lighting

- Other

- Furnace Construction Maintenance

-

Mixing Technology

- Mixing Technology List

-

SM Engineering Equipment

- SM Engineering Equipment List

-

Heating and Cooling Systems

- Heating and Cooling Systems List

- Saccharification system for bio-ethanol production

- Adhesive Temperature Adjusting System

- Coating Liquid Precision Temperature (viscosity) Adjusting System

- Scrambled Eggs Continuation Manufacturing System

- Condiment Miso Heat Sterilization System

- Starch Gelatinization System for Paper Manufacturing

- Flour Paste Manufacturing System

- PVA Continuous Dissolution System

- Seasoning Liquid Heating Sterilization Cooling System

- Automated Oxidized Starch Production System

- In-line Starch Saccharification System

- Water Heating System

- Mixing Systems

- Powder and Liquid Dispersion System

- Reaction System

- Laboratory Test Systems

-

Heat Exchangers

- Heat Exchangers List

- Heat Exchangers

- Reaction

-

Static Mixer (SM)

- Static Mixer (SM) List

- Gas absorption(Option)

- Homogenization

- Miixing

- Option Parts

- Search by industry or usage

- Cooker / Steam Mixer

- Cutting Machine (Thin Cut Master : TCM)

-

Filtration Systems

- Filtration Systems List

- Search lubricants

-

Coolant Filtration Systems

- Coolant Filtration Systems List

- Centrifuge

- Coolant Tank Unit

- Magnetic Separator

- Cyclone Separator

- Paper Filter

- Backwash Filter

- Centralized Filtration Systems

- Search filtration materials

- Filtration Related Systems

- Ceramic filter

- Technical Support

- Catalog Download

- About Our Sales Offices

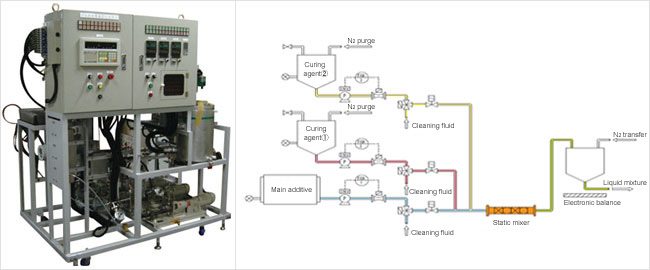

The system continuously mixes two or more raw ingredients for resin.

This new system replaces tradition batch systems which use a tank for mixing.

Advantages

- Productivity is greatly improved by going from a batch system to a continuous system.

- Products no longer have to be produced in separate batches, which enables better quality, the elimination of air bubbles, and consistent product supply.

- Because it’s an inline process, you can significantly improve the work environment.

- The system monitors the balance between coating liquid production volume and consumption volume using an electronic balance, and automatically controls coating liquid production speed. It also prevents inconsistent mixture ratios in spite of adjustments to the production speed.

- It is equipped with an automatic cleaning mode, and cleaning can be performed by pushing just one button.

Applications

- Film coating liquid mixing

- Mixing epoxy and acrylic resins

- Mixing liquid ingredients for urethane

Sample Specifications

| Processing Capacity | Main additive: 41.3 - 124.0 g/min Curing agent (1): 7.02 - 21.07 g/min Curing agent (2): 1.65 - 4.96 g/min |

|---|---|

| Utilities | Electricity: 200 V three-phase Air: 0.49 MpaG |

| Dimensions and Weight | 1700L×1085W×2000H (mm) Approx. 800 kg |