NST Series

Engineering

-

Heating Furnaces / Kilns

- Heating Furnaces / Kilns List

-

Drying Furnace

- Drying Furnace List

- Batch Kiln

- Far Infrared Conveyer Furnace

- Other Drying Furnaces

- Roll to Roll Far-infrared Heating Furnace

- Far Infrared Heater

-

Firing Kiln

- Firing Kiln List

- Roller Hearth Kiln

- Pusher Kiln

- Rotary Kiln

- Other

- Batch Kiln

- Refractory

-

Search by industry or usage

- Search by industry or usage List

- Semiconductors

- Energy

- Electronics

- Automobiles

- Displays and lighting

- Other

- Furnace Construction Maintenance

-

Mixing Technology

- Mixing Technology List

-

SM Engineering Equipment

- SM Engineering Equipment List

-

Heating and Cooling Systems

- Heating and Cooling Systems List

- Saccharification system for bio-ethanol production

- Adhesive Temperature Adjusting System

- Coating Liquid Precision Temperature (viscosity) Adjusting System

- Scrambled Eggs Continuation Manufacturing System

- Condiment Miso Heat Sterilization System

- Starch Gelatinization System for Paper Manufacturing

- Flour Paste Manufacturing System

- PVA Continuous Dissolution System

- Seasoning Liquid Heating Sterilization Cooling System

- Automated Oxidized Starch Production System

- In-line Starch Saccharification System

- Water Heating System

- Mixing Systems

- Powder and Liquid Dispersion System

- Reaction System

- Laboratory Test Systems

-

Heat Exchangers

- Heat Exchangers List

- Heat Exchangers

- Reaction

-

Static Mixer (SM)

- Static Mixer (SM) List

- Gas absorption(Option)

- Homogenization

- Miixing

- Option Parts

- Search by industry or usage

- Cooker / Steam Mixer

- Cutting Machine (Thin Cut Master : TCM)

-

Filtration Systems

- Filtration Systems List

- Search lubricants

-

Coolant Filtration Systems

- Coolant Filtration Systems List

- Centrifuge

- Coolant Tank Unit

- Magnetic Separator

- Cyclone Separator

- Paper Filter

- Backwash Filter

- Centralized Filtration Systems

- Search filtration materials

- Filtration Related Systems

- Ceramic filter

- Technical Support

- Catalog Download

- About Our Sales Offices

Technical Support

Basic Functions

-

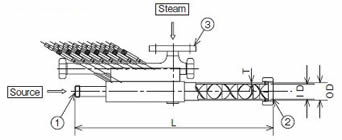

The Noritake Cooker is ideal for heating highly viscous liquids directly with steam. The cooker consists of a steam header, injection nozzles and a dispersion section, static mixer. The steam injected into the high viscosity liquid is forcefully agitated so that compression and heating occur in an instant.

Therefore, it can be taken to the target temperature instantly. In addition, it can be used with starch-like materials that quickly gain viscosity when heated. These units are widely used in the food, paper pulp and chemical industries.

Finally, vibrations and sounds created during steam condensation processes are virtually eliminated. A liquid with a uniform distribution of temperature is quickly attained and temperature control is both simple and precise.

The simple construction of this series allows for simple CIP and disassembled cleaning.

Standard Specifi cations

| Diameter | 1/2”-3” (3”+ diameter options available. ) |

|---|---|

| Material | Unit:304S.S Element:316S.S |

| Number of Elements | 6 |

| Element Fixing | Welded Ring (Removable Element) |

| Fixing | Ferrule, IDF ScrewNut, JIS10K Flange |

| Finish | Sanitary finish |

PAT.1485351

PAT.1543109

Model Code Chart

Dimensions

| Model | (1) Source In |

(2) Processed fluid Out |

(3) Steam In JIS10K (IDF) |

Capacity L/h |

Steam kg/h |

Outside Diameter (OD) 0Dmm |

Inner Diameter (ID) IDmm |

Thickness Tmm |

Length Lmm |

Mass kg |

|---|---|---|---|---|---|---|---|---|---|---|

| NST-D15-3/IDF(V) | 1S | 1S | 1/2"(1S) | 50-120 | ~22 | 21.7 | 14.3 | 3.7 | 320 | 4 |

| NST-D20-3/IDF(V) | 1S | 1S | 1/2"(1S) | 100-400 | ~75 | 27.2 | 19.4 | 3.9 | 375 | 5 |

| NST-D25-3/IDF(V) | 1S | 1 1/4S | 3/4"(1S) | 200-600 | ~110 | 34.0 | 25.0 | 4.5 | 470 | 7 |

| NST-D40-3/IDF(V) | 1 1/2S | 2S | 1"(1 1/2S) | 400-1,500 | ~280 | 48.6 | 41.2 | 3.7 | 590 | 12 |

| NST-D50-3/IDF(V) | 1 1/2S | 2 1/2S | 1 1/2" | 700-3,000 | ~560 | 60.5 | 52.7 | 3.9 | 755 | 18 |

| NST-D65-3/IDF(V) | 2 1/2S | 3S | 2" | 1,200-5,000 | ~930 | 76.3 | 65.9 | 5.2 | 910 | 25 |

| NST-D80-3/IDF(V) | 2 1/2S | 3 1/2S | 2 1/2" | 2,000-7,000 | ~1,300 | 89.1 | 78.1 | 5.5 | 1200 | 32 |

pressure:0.5MPaG

Related Products

| Use | Examples | Recommended items |

|---|---|---|

| Direct heating Inject steam directly into liquid to condense it |

●Warm water production ●Heating of chemicals |

SME-V series (Steam mixer) |

| ●Heating of slurry ●Heating /sterilization of the highly viscous liquid |

NST series (Noritake cooker) |

|

| Direct cooling Inject cold water directly in steam and vaporize |

●Temperature decrease and low pressure steam production | DSM series (SM De-superheater) |